This website uses cookies to give you the best and most relevant online experience. If you continue using this website, we'll assume you are aware of and accept our use of cookies.

Laser Welding

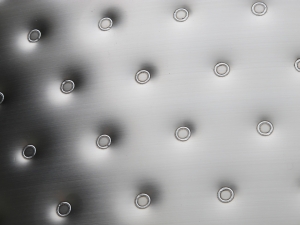

Laser welding is a computer-controlled welding technology used to join pieces of metal using a laser beam. The advantage of laser welding, compared to traditional welding procedures, is a noncontact energy supply with no direct mechanical loads on the product surface. This technology creates a very stable and nonporous weld that retains the metallic shine of the base material.

- contact-free material processing: a welding process based on the principle of melting the basic material with no direct mechanical contact with the product surface

- low heat input: limited and strictly controlled (time, location) heating, which reduces the possibility of any basic material deformations

- high-quality welds: all welds are extremely accurate and consistent – no need for additional finishing, laser welds retain the metallic shine of the base material

- flexibility: it enables different welding lines, welding in spirals and irregular forms; any openings and connectors on the basic surface can be easily avoided

- high welding speed: significantly faster than traditional welding techniques

Laser welding technique

Laser welding technique