The best from nature

Natural fat-soluble bioactive compound extraction systems

PILOT SYSTEMS

-

The system is controlled via touch screen control panel or computer using an intuitive control system software . The software is designed in accordance with the GMP standard; manual operation is limited to vessel filling and emptying.

-

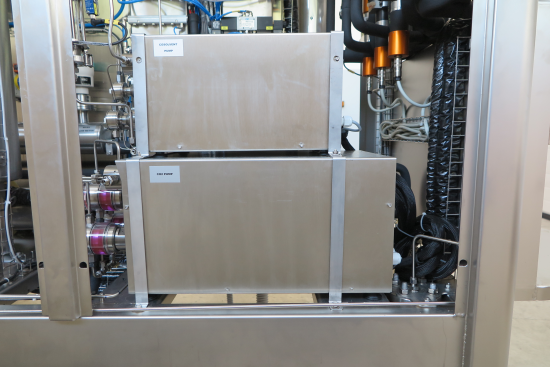

Electrical cabinet, which includes control logic, switching electronics, and relays, as well as the main switch for system operation control (ON/OFF).

-

Extraction is carried out in high-pressure extraction vessels (EV), equipped with an automatic temperature regulation system. The vessels have a threaded cap. They are made of stainless steel and certified in accordance with the PED directive. Pilot models can have 1 to 3 extraction vessels with a volume of 5 or 10 L.

-

Products are selectively collected in three high-pressure collection vessels. Pilot MoSES systems are equipped with four collection vessels with a volume of two liters. The vessels also have a threaded cap and a discharge valve. They are made of stainless steel and certified in accordance with the PED directive.

-

Used for product collection.

Pivovarna ZAJC 1725 // Slovenia

Cerkno

Pivovarna ZAJC is an innovative young craft brewery in Reka, a small village near Cerkno. The brewery is a perfect example of how to connect with your community as a business. They work with local restaurant owners and other tourism service providers, and promote the local culinary offer. Their work is a blend of modern brewing trends and tradition, which remains very important to them. They are currently preparing a museum of beer brewing, where visitors will be able to discover the history of this craft and learn more about the brewing process itself.

Need some help?

Fill out the form below

We approach every project individually, with every customer's wish and need in mind. A group of experts from various fields work together to find the best solution for our investor. How can we help you? Fill out our form or call us and tell us about your plans. Together, we'll find the right answer.