Automation can be described as automatic and intelligent system management that facilitates the operator's work and reduces the chances of human error during the work process.

In complex processes, such as extraction under supercritical conditions (high pressures and elevated temperatures), automation reduces numerous risks and ensures standardized system operation in accordance with occupational safety standards. Automation also ensures optimal system efficiency during operation and has a significant effect on the quality of the final product.

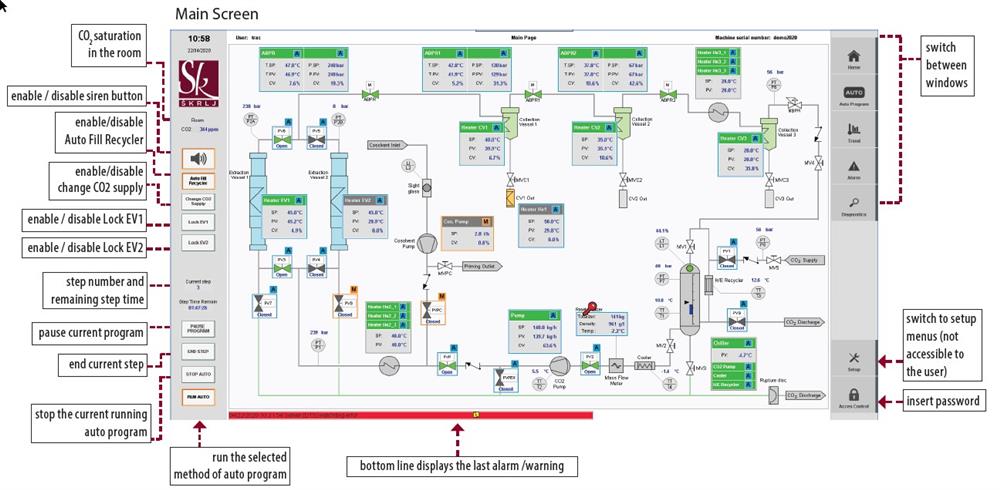

Figure 1: Main screen for system control via PLC

Central controller

Our extraction systems are equipped with a central programmable logic controller (PLC), which is operated via touch screen. Apart from managing system operation, the interface also allows you to monitor the extraction parameters in each phase of the extraction process, view past events, and create reports. Depending on their authorizations, each operator can access the system with their own user profile; the system records all interventions of each individual operator, which is also evident in the final report.

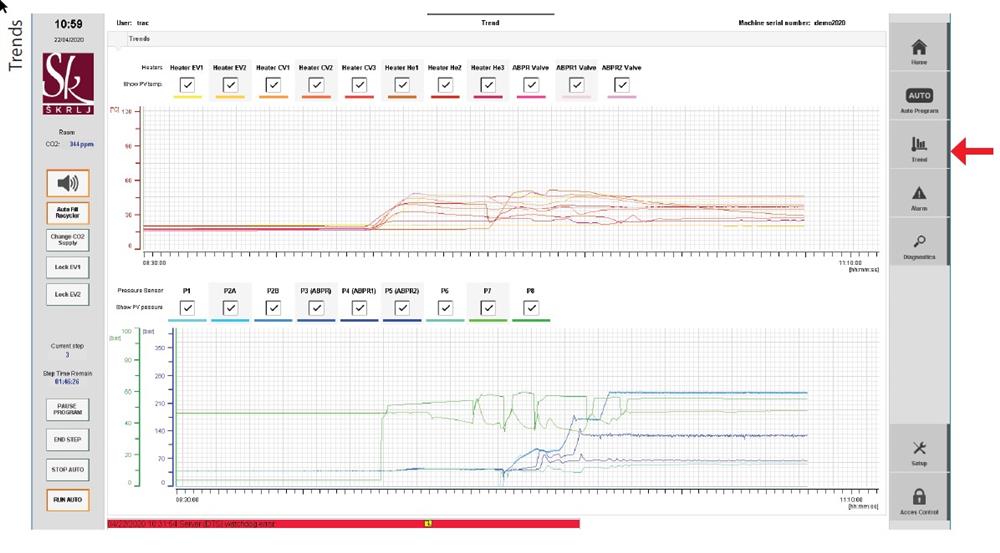

Figure 2: Graph of process parameter value changes during extraction

Automatically controlled heating elements

All extraction processes are performed under supercritical conditions. One of the conditions for reaching the supercritical state is establishing a suitable critical temperature. MoSES systems are equipped with built-in automatically controlled heating elements, which are used to achieve and regulate the critical temperature and enable extraction at temperatures up to 80 °C.

Temperature and pressure sensors

SK Škrlj extraction systems are equipped with built-in electronic and mechanical protection devices (sensors) that protect the system against operational and mechanical errors and thus ensure a high level of operator safety.

Recipes

If you plan to purchase an SK Škrlj extraction system, we prepare for you a preliminary system setup according to the planned application. We test all important parameters in each extraction phase and, based on the obtained results, adjust the extraction method accordingly. We also help you optimize the extraction method during system startup, which enables immediate use and optimal process efficiency. The extraction system's extraction method storage facilitates system use, improves process repeatability, and enables a higher level of product standardization.

Diagnostics

In the event of any errors or process deviations, our experts can run real-time remote system diagnostics, eliminate errors, and provide technical support for process and extraction method optimization.

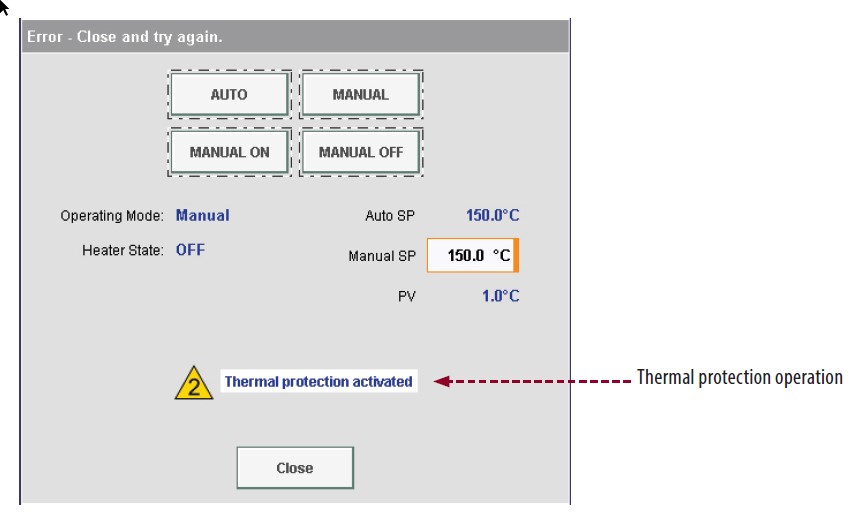

Figure 3: Example of safety warning due to operation error

Manual mode

Škrlj extraction systems also enable full manual control, which gives the more experienced users the opportunity to bypass the established recipes and preset extraction methods. The central controller retains its safety control function during operation even if the system is switched to manual mode; the system immediately issues a warning which alerts the operator to this dangerous move and the potential deviations, inconsistencies, or hazards.