The best from nature

Natural fat-soluble bioactive compound extraction systems

Supercritical CO2 extraction

Each substance in the gaseous state can enter the supercritical state by changing the pressure and temperature. The most commonly used gas is carbon dioxide, as it is easily accessible, relatively harmless, affordable, and enters the supercritical state under relatively undemanding physical conditions.

Carbon dioxide (CO2) is a unique solvent whose dissolving power can be regulated by changing the pressure and temperature during the extraction process. When the temperature and pressure exceed 31 °C and 74 bar(g), carbon dioxide enters the supercritical state. If the temperature drops below 31 °C, carbon dioxide enters the subcritical state.

Supercritical and subcritical gases act as solvents and can remove oils and hydrophobic components from plant materials. If the pressure is lowered under 41 bar(g), the gas enters its natural (gaseous) state and loses its dissolving power. This means it no longer has the ability to hold on to the dissolved oils and other removed components, which are consequently released in the form of a liquid, paste, or a solid product. The result is a completely natural extract with no solvent residue, which is why this extraction method is considered environmentally friendly.

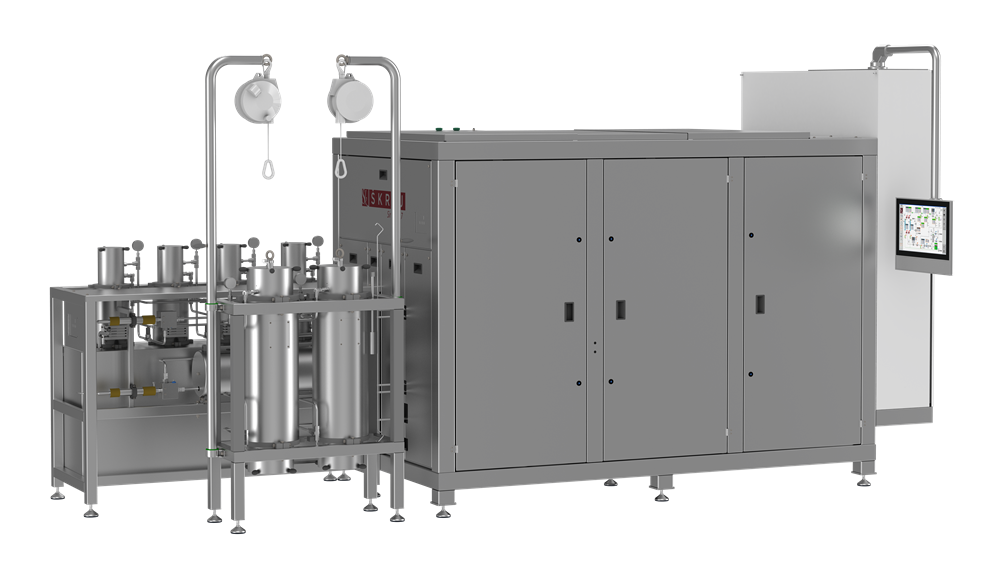

MoSES extraction system

We have dedicated the last five decades to the development of process equipment for various sectors. Our product range includes standard supercritical extraction systems, but we also develop models which are adapted to the needs of our customers. The Škrlj MoSES system – certified and tested in accordance with EU standards – is a fully automated system designed for the sub- and supercritical CO2 extraction of natural bioactive compounds.

Due to the pressure loads, all pressure components (high-pressure pumps, pressure regulation system, high-pressure vessels) must be manufactured and tested in accordance with the applicable pressure equipment standards. The MoSES system is equipped with built-in electronic and mechanical protection devices which protect the system against errors and malfunctions and thus ensure a high level of operator safety.

Under construction

Laboratory systems - coming soon!

MoSES 1.5.1, 1.5.2, 1.10.1, 1.10.2

Pilot extraction systems with one, two, or three extraction vessels.

MoSES 1.25.1, 1.25.2, 1.25.3, 1.50.2, 1.50.3

Industrial extraction systems with one, two, or three extraction vessels.

Why choose us?

Modular design

The basis of the entire system is a compact support frame with a control cabinet, as well as a gas supply and pressure regulation system, while . ...More

The basis of the entire system is a compact support frame with a control cabinet, as well as a gas supply and pressure regulation system, while the modules with temperature-controlled extraction and collection vessels can be varied. This means that system flow and efficiency can be easily controlled and upgraded by changing the configuration of the extraction vessels or their sequence.

The system can optionally be equipped with an additional pump for organic solvent supply, which can improve extract quality and final extraction efficiency. This option also enables more optimal system cleaning in accordance with GMP guidelines.

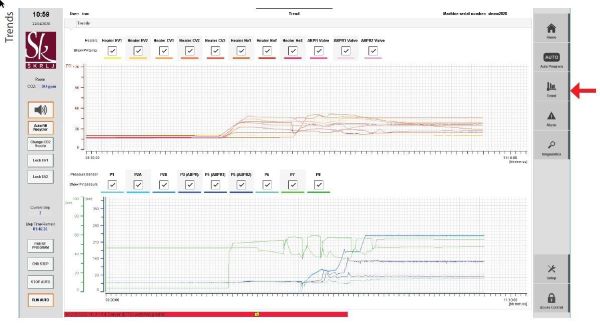

Automation

The system is equipped with a built-in HMI (PLC Programmable Logic Controller) that enables you to automatically carry out the extraction process. Automation reduces the number of human errors and ensures better system efficiency ...More

The system is equipped with a built-in HMI (PLC Programmable Logic Controller) that enables you to automatically carry out the extraction process. Automation reduces the number of human errors and ensures better system efficiency, improved process repeatability, and a more rational energy consumption. An upgrade with a GMP software package also ensures traceability and documentation in each phase of the process. See also Fully automated extraction system.

Standards

Škrlj MoSES systems are designed and manufactured in accordance with EU directives, their quality is confirmed by various certificates. Directives: ...More

Škrlj MoSES systems are designed and manufactured in accordance with EU directives, their quality is confirmed by various certificates.

Directives:

- Machinery Directive (2006/42/EC)

- Electromagnetic Compatibility Directive EMC (2014/30/EU)

- Low Voltage Directive LVD (2014/35/EU)

- Pressure Equipment Directive PED (2014/68/EU) (see also Pressure equipment and the PED)

Certificates:

- EU Declaration of Conformity

- ISO 9001:2015

- EN ISO 3834-2

- AD 2000-Merkblatt HP 0 (2017-10) and EN13445-4:2014 + EN ISO 3834-2:2006

- PED Directive 2014/68/EU (Module H/H1)

Use

MoSES extraction systems are often used to produce bioactive compounds from plant material when a high degree of extract purity is required. Notable applications: ...More

MoSES extraction systems are often used to produce bioactive compounds from plant material when a high degree of extract purity is required. Notable applications:

- hemp paste production

- coffee and tea decaffeination

- hop extract production for beer brewing

- production of plant extracts for the pharmaceutical, cosmetic, and food industries

- production of essential oils which are used as ingredients in cosmetics (perfumes, soaps, detergents)

- production of essential oils from lavender, chamomile, and citrus fruits

- production of volatile essential oils that contain esters, terpenes, aromatics, alcohols, aldehydes, ketones …

- production of algae extracts that contain sterols, carotenoids, antioxidants, fatty acids, peptides

- polymer impregnation

- textile dyeing

- cleaning of orthopedic implants

Nebó Winery // Slovenia

Neblo

Nebó Winery is a new winery located in Neblo, a small village in the Goriška Brda region. It is the westernmost winery in Slovenia. The diverse locations of the vineyards, the vast selection of grape varieties and the large number of different wines also require a greater number of tanks in which the wines can mature and develop their full flavor.

Need some help?

Fill out the form below

We approach every project individually, with every customer's wish and need in mind. A group of experts from various fields work together to find the best solution for our investor. How can we help you? Fill out our form or call us and tell us about your plans. Together, we'll find the right answer.