What is PED?

The Pressure Equipment Directive or PED (2014/68/EU) sets out the requirements that pressure equipment manufacturers must meet if they want to sell their products in Europe. It applies to the design, manufacture, and conformity assessment of pressure equipment and assemblies with a maximum allowable pressure PS (the maximum pressure the components can handle based on the design) greater than 0.5 bar. Pressure equipment and assemblies may be made available on the market or put into service only if they satisfy the requirements of the Pressure Equipment Directive, i.e., if they are manufactured in accordance with the Directive, if they are properly installed and maintained and if they are used for their intended purposes.

With the PED Directive, the European Union has harmonized the requirements that ensure the safety of the pressure equipment used within the European Economic Area - EEA. This ensures suitable user safety, but it also means that the manufacturers of pressure equipment that satisfies the requirements of the PED Directive can offer their products in all members of the EEA, without additional permits for each individual country.

What is pressure equipment?

The term pressure equipment means pressure vessels, piping, safety and pressure accessories, including, where applicable, components attached to pressurized parts (flanges, nozzles, couplings, supports, lifting lugs, etc.).

Due to the internal pressures and the substances contained or stored within, pressure equipment can pose a danger to people and objects in the vicinity, as well as the environment. Based on the danger it presents, pressure equipment can be classified into two groups:

- low risk equipment,

- high risk equipment.

The duties of a pressure equipment manufacturer

Each pressure equipment manufacturer must draw up the required technical documentation, which will enable pressure equipment conformity assessment with the requirements of the PED Directive. The documentation must, among other things, contain design calculations and enable both material and production process traceability.

If the pressure equipment and assemblies meet the requirements of the Directive, which is confirmed by a notified body, the manufacturer can prepare a Declaration of Conformity and affix the CE marking, which is accompanied by the identification number of the PED notified body that registered the manufacturer's finished product.

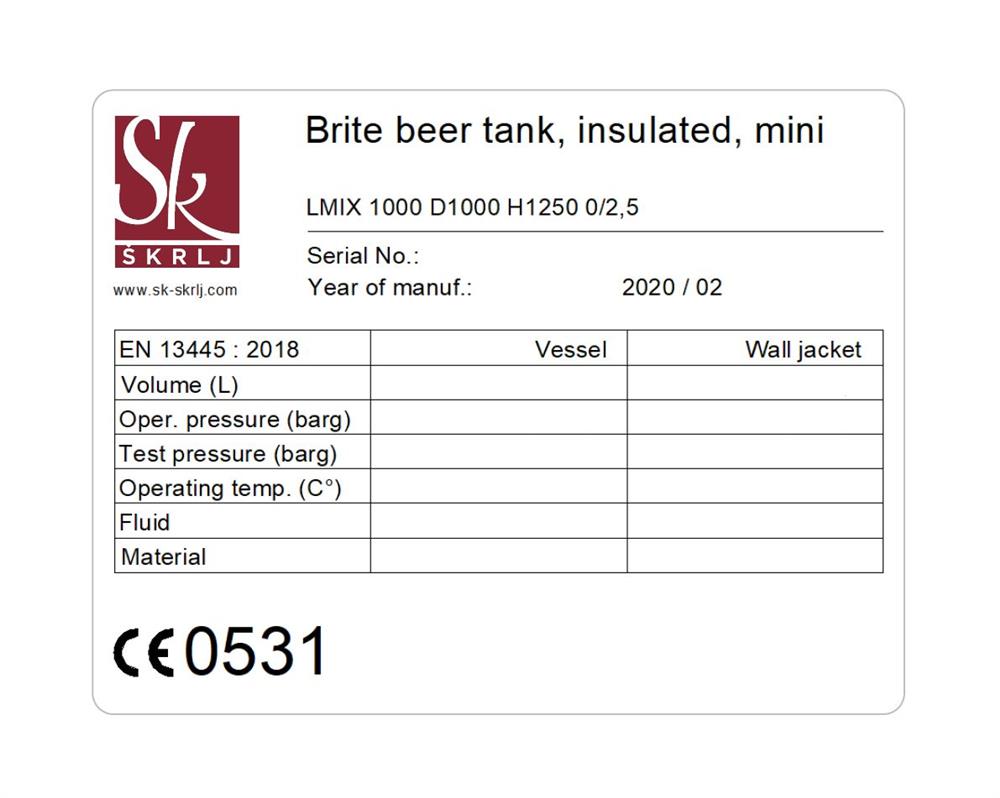

The manufacturer must also create a product identification plate, which must be fixed onto a visible part of the pressure equipment or assembly. The identification plate must contain all the information required by the Directive (name, serial number, pressure values, etc.) and the CE marking, as well as the modules or standards used during manufacturing.

Declaration of conformity

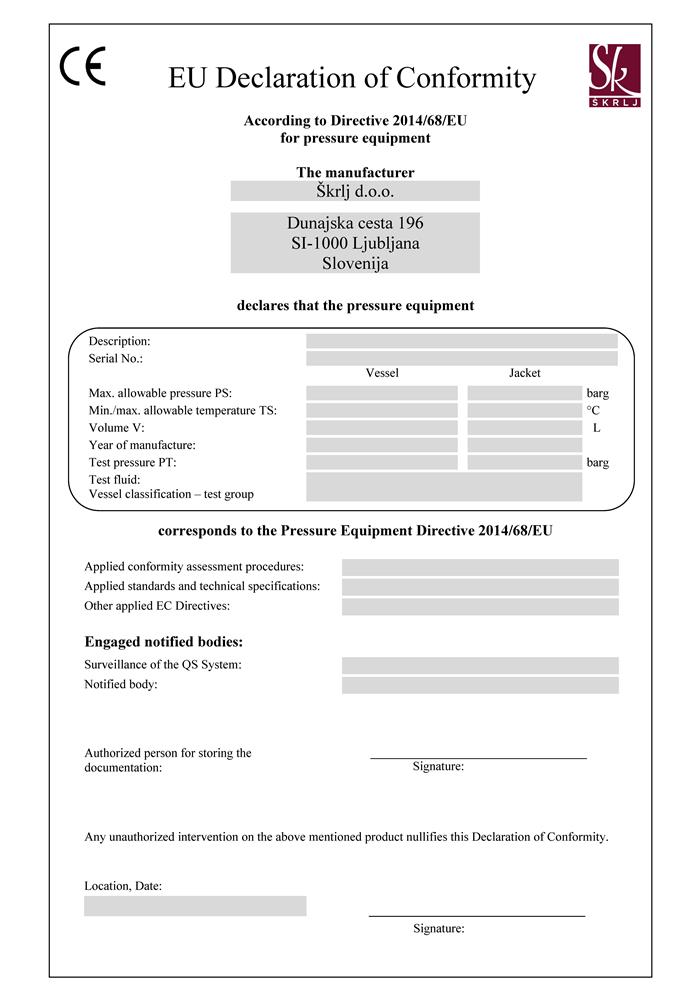

The EU Declaration of Conformity confirms that a product meets the requirements of the Pressure Equipment Directive i.e. the requirements of the European Union.

The Declaration of Conformity must contain:

- the name and full address of the manufacturer or their authorized representative

- pressure equipment identification (name, product type, production batch or serial number),

- the applied directive(s), regulations, and standards,

- name of the manufacturer's signatory or their authorized representative,

- approval by a notified body for conformity assessment,

- place and date of issue.

What does this mean for the user?

Choosing which pressure equipment to buy can be very difficult as there are many different manufacturers. The price of the product can be, in many cases, the determining factor, although basing your choice on this often leads to poorer quality and the initially lower price can later increase significantly due to additional costs. When deciding to purchase pressure equipment, especially from outside of Europe, you must make sure that the manufacturer also provides you with the required documentation which ensures that the equipment complies with the PED requirements, enables you to register the product with the competent authority, and ensures safe product use. If the documentation is incomplete, the importer or the person who places the pressure equipment on the EU market must subsequently carry out all conformity assessment procedures (calculation, testing, etc.). The entire process can prove costly and it may even be in vain, as there is still a possibility that the pressure vessel will not obtain approval for further use.

Each pressure equipment user must take all necessary safety measures in order to ensure his safety and the safety of his employees. Inspections and maintenance work depend on the group the product belongs to:

- Low-risk equipment: The user is responsible for safe product use. They must follow the manufacturer's instructions for equipment installation, connection, use, and maintenance, as well as carry out the inspections and tests specified by the manufacturer and document them accordingly.

- High-risk equipment: The first inspection and all subsequent periodic inspections are performed by an approved inspection body with which the user concludes a contract. The inspection body also keeps records of the pressure equipment.

Every pressure equipment user should be aware that even a 500-liter tank with a pressure of 2.5 bar is deemed as high risk. This means that most beer tanks are in this group and their users must:

• arrange the first pressure equipment inspection;

• arrange subsequent periodic inspections;

• notify the competent authority within eight days of the start and end of use of pressure equipment;

• notify the competent authority within eight days of any change to the data contained in the protocol sheet;

• in the event of a change of ownership, hand over the pressure equipment records and all associated documentation to the new owner.

During pressure equipment installation, use, and inspection it is necessary to take into account the regulations, standards, and provisions, applicable in the country where the equipment is installed, as they may differ. Make sure you check the regulations, applicable in your country, before equipment installation.