Winery projects

From concept to realization

From a financial and business standpoint, building a winery can be a very demanding project. Some winemakers would even call it their life project. New business premises must be woven into the cultural landscape and has to adapt to the terrain, natural landscape and tradition of the local environment. At the same time, the winery itself must be designed so that it enables easy work with minimal unnecessary paths and as little physical effort as possible.

For more advice on what to bear in mind while you plan such a project read the following blog posts.

Winery design and construction

Do you plan on building a brand new winery? Or do you maybe want to renovate your existing premises, perhaps make some additions? Carefully planned and informed decisions in the initial phase can help you avoid unnecessary mistakes, dissatisfaction, and additional costs that often result from a wrong approach to a project like this...

Tank, platform, walkway and equipment placement

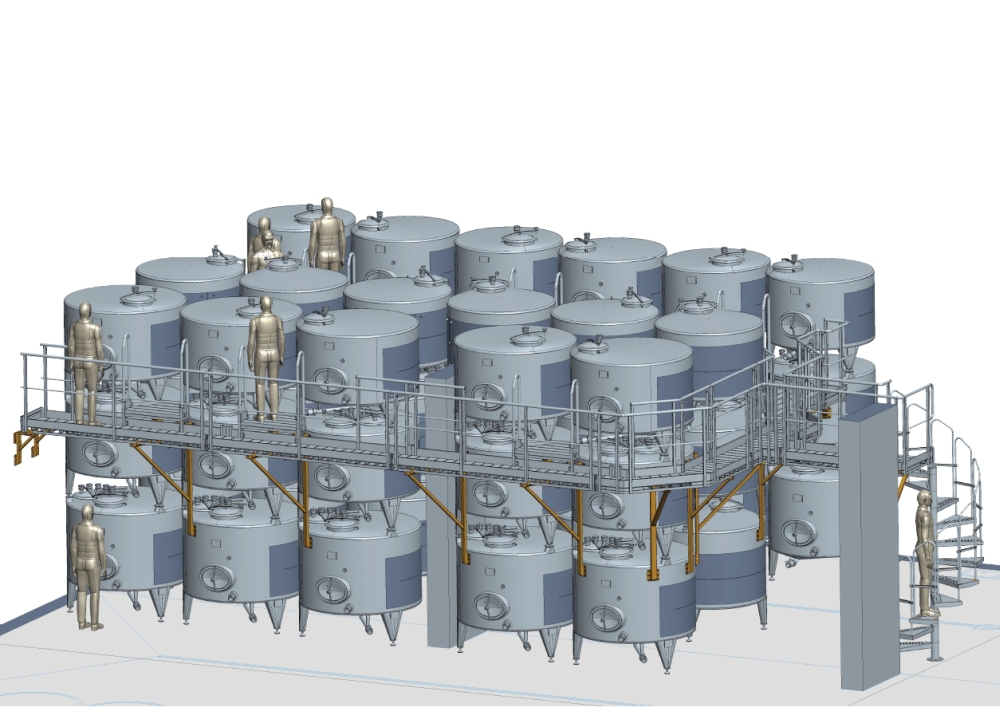

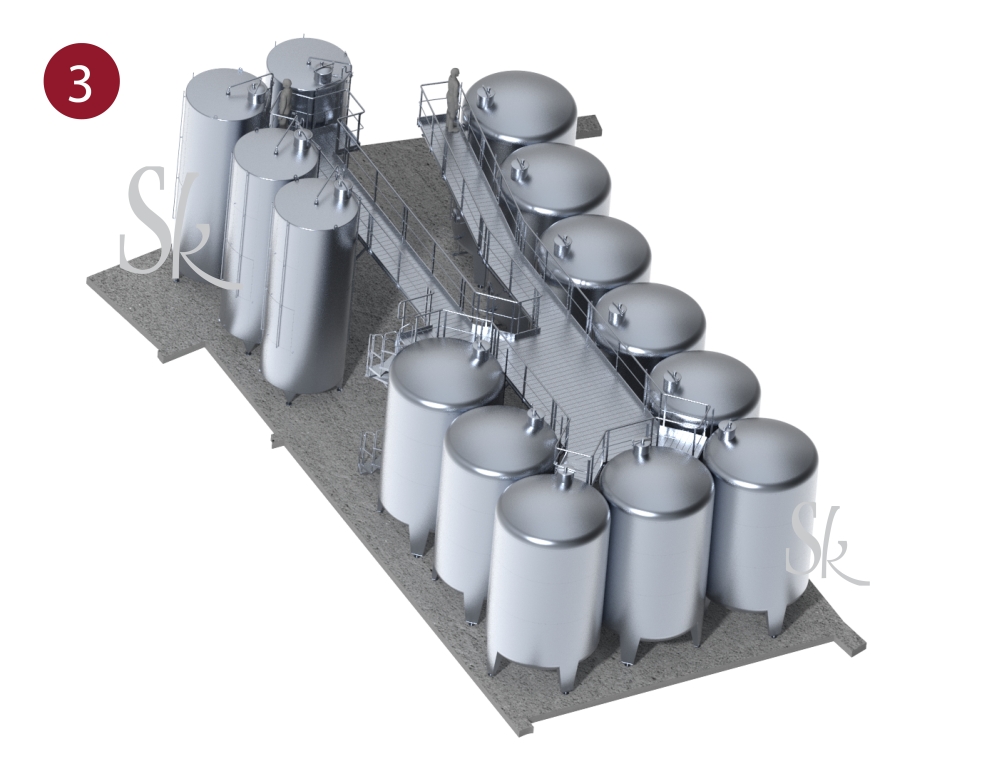

There’s more to planning a winery layout than simply choosing tanks with suitable capacities. The main goal is to create a functional space that will encourage creativity and where you will be happy to work and welcome your guests...Platforms, staircases, industrial ladders

Wineries often consist of multiple tanks of different heights, which means the winemaker must arrange passages between different levels or access to tanks at elevated heights. This often includes taking into account and adapting the new layout in accordance with various existing objects. Here’s where we come in. Our experienced designers can help you find the optimal solution and create a winery layout, which includes all winery equipment and platforms ...

Temperature control equipment

A precise and effective temperature control system is extremely important in food processing. Temperature affects virtually all biological, physical, and chemical processes that occur during food processing and affect the product's final properties. A temperature control system gives the user an active role and enables them to regulate the processes taking place inside the tank and guide them in the desired direction ...

- analysis of customer demands and requirements

- a project team performs a detailed review of the submitted documentation (plans, drawings, calculations, desired capacity, infrastructure)

- conversation with client, initial project coordination

.jpg)

- review of customer demands for compliance with applicable technical standards

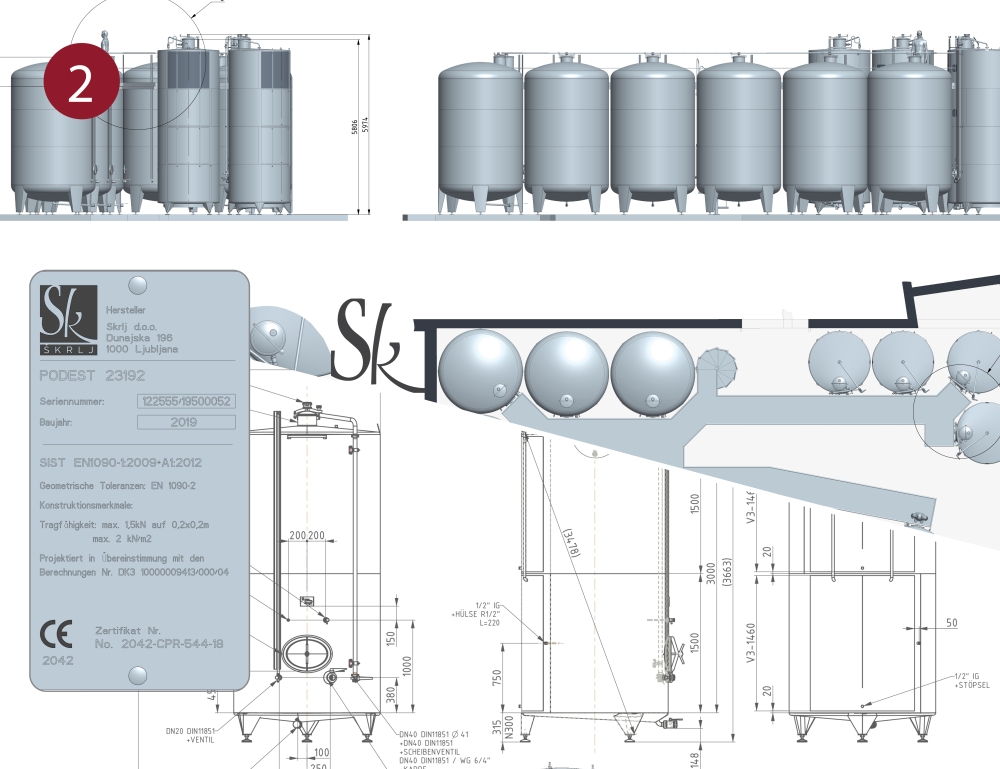

- preparation of basic drawing with tanks, platforms, staircases, and other objects, which presents their layout at the installation site

- material selection, agreement on inside and outside surface finishing, as well as weld finishing, selection of suitable connectors, additional equipment

- preparation of non-binding sales offer

- after receiving an order it is time to determine the final technical and sales specifications and to prepare the final drawing

- the project is also presented with a 3D model, which enables easier plan and layout review

- preparation of sales order confirmation, expected production end date is determined

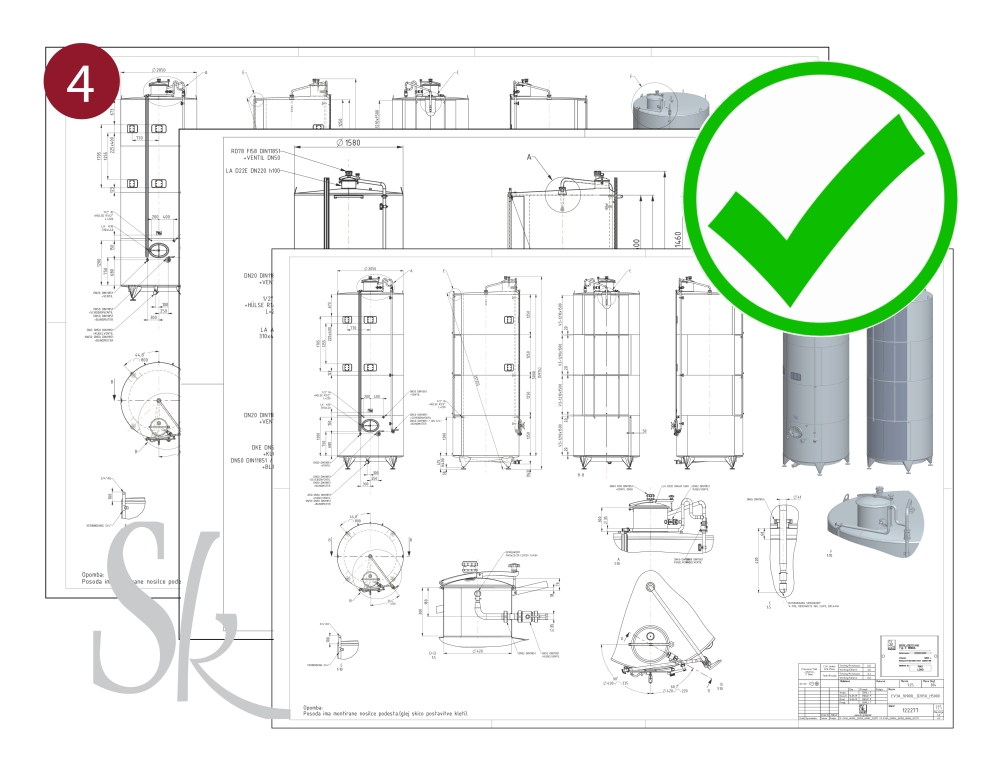

- preparation of detailed drawings for each product, listed in the sales order confirmation

- the customer carefully reviews the technical drawings and the order for any inaccuracies

- our team is always available for further clarification

- once all drawings and sales specifications are confirmed by the customer, the order enters the production preparation stage

- the confirmed order is passed over to our production planning department, where we prepare all the documentation needed for a successful production process

- sales and production processes are run using the SAP program, which enables fast and organized information flow

- production is carried out in accordance with precisely defined work orders, control is carried out throughout the production process

- modern CAD technology (computer-aided design) enables precise project design, technological process and material traceability during production, and organized product documentation

- customers can view the status of their order on the SK Škrlj website

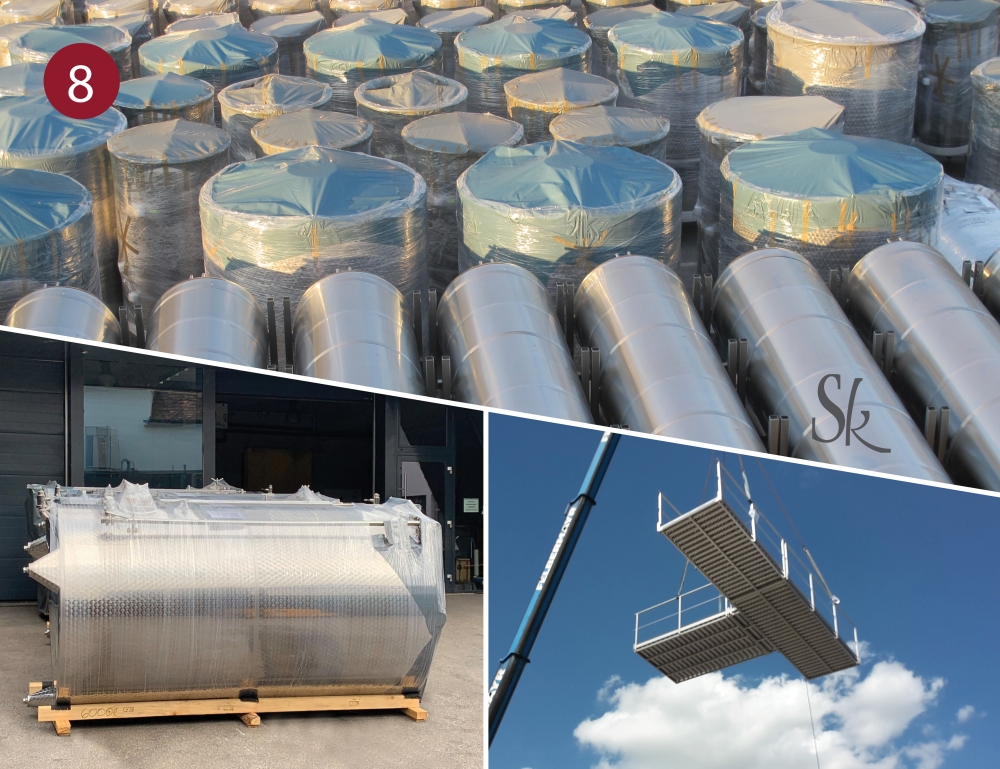

- the finished product is cleaned

- before delivery we perform a final inspection of the product and all its accompanying equipment

- preparation of accompanying documentation (instructions for use and maintenance, instruction manual of built-in equipment, technical drawings, statements, certificates)

- entire product documentation is available to the customer on the SK Škrlj website

- the product is prepared for safe transport

- transport is organized based on the agreement with the customer, we prepare an order delivery schedule

- customers are provided with technical support even after their purchase is completed (phone, e-mail, web conference)

- if problems arise during start-up, they are usually resolved remotely (phone, e-mail, web conference

- first device start-up and initial training can be carried out by SK Škrlj (upon agreement)

- quick response in case of maintenance or repair requests

- instruction manual and technical documentation are available to the customer on the SK Škrlj website

WINERY

- Winery

- Platform and staircase

- Number of tanks: 25

- Nominal capacity: 233.200 L

- Link: Weingut Burger Josef

Okavango Craft Brewery // Botswana

Maun

Established in 2019 in the city of Maun, which is located in Northern Botswana, Okavango Craft Brewery is the first licensed microbrewery in the area. It is named after the Okavango Delta, home to one of the largest elephant populations in the world. While their primary goal is to make top quality beer, they've also made it their mission to reduce their environmental impact and to support local economies, as well as local "elephant-aware" farmers who have integrated sustainable farming methods.

Need some help?

Fill out the form below

We approach every project individually, with every customer's wish and need in mind. A group of experts from various fields work together to find the best solution for our investor. How can we help you? Fill out our form or call us and tell us about your plans. Together, we'll find the right answer.