The best from nature

Natural fat-soluble bioactive compound extraction systems

Extraction

Extraction equipment

We design and manufacture extraction equipment for users in need of a simple device to obtain small amounts of extract, as well as more complex equipment for industrial use. Our offer includes systems that use carbon dioxide as a solvent (supercritical CO2 extraction), but we are also developing systems for supercritical water extraction (SWE). Given the investment cost, complexity of use, and extract quality, each system has its advantages and disadvantages.

Supercritical and subcritical extraction

Supercritical and/or subcritical extraction is a process used to obtain extracts and other substances using gases which are under super- or subcritical conditions. Supercritical gases have all the physical properties of gases, but they are incompressible and possess the same dissolving power as liquids.

The advantage of supercritical extraction is that it enables you to influence the dissolving power simply by changing the pressure and temperature, which means that the extraction process can be adapted to obtain specific substances from a collective matrix. This method is used in the production of bioactive compounds from herbs and other plants when a high degree of extract purity is required, especially in the pharmaceutical and food industries. It is most known for its use in the production of hemp paste and decaffeinated coffee and tea.

One of our main goals has always been finding new user-friendly solutions, which is why we have made extraction equipment development one of our main priorities.

Trusted by

More about CO2 extraction

Supercritical extraction throughout history

The supercritical state of fluids was discovered by the French Baron Charles Cagniard de la Tour in 1822, although the true significance of his discovery and the possibilities it opens up became apparent only later ...

Smart Investment in Slovenian Supercritical Extraction System

PharmaHemp, one of the world's leading companies in the field of research, development, processing, and laboratory testing of raw materials and industrial hemp products has taken a major step forward by acquiring a highly efficient CO2 extraction system that can be used to obtain plant extracts for the food, cosmetic, and pharmaceutical industries.Fully automated extraction system

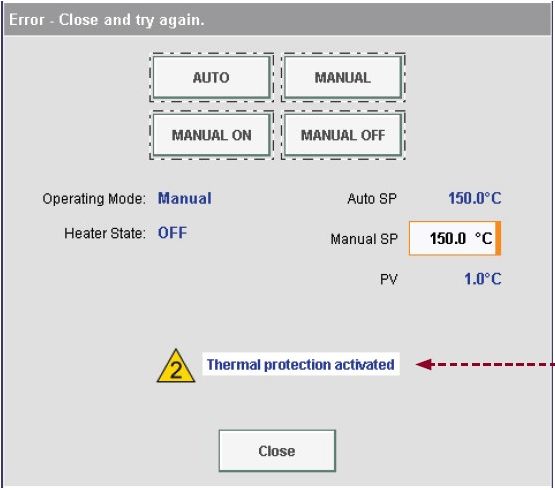

In complex processes, such as extraction under supercritical conditions (high pressures and elevated temperatures), automation reduces numerous risks and ensures standardized system operation in accordance with occupational safety standards. Automation also ensures optimal system efficiency during operation and has a significant effect on the quality of the final product.

Our customer stories

Purchasing our own extraction system was an important step, as was choosing the right manufacturer. What ultimately tipped the scales in favor of SK Škrlj was their proximity, high-quality materials and components, technical support, and personal approach to projects, as they always try and take into account customer demands and expectations.

Compared to low-cost products currently available on the market, the Škrlj system detects potential hazards and is fully automated which prevents errors due to human factors. In case of deviations at any stage of the process, the system reports an error and alerts the operator. Diagnostics can also be run remotely, as the system can be connected to a Wi-Fi network.

Boštjan Jančar, Ph.D. (CTO of PharmaHemp)

Pivovarna ZAJC 1725 // Slovenia

Cerkno

Pivovarna ZAJC is an innovative young craft brewery in Reka, a small village near Cerkno. The brewery is a perfect example of how to connect with your community as a business. They work with local restaurant owners and other tourism service providers, and promote the local culinary offer. Their work is a blend of modern brewing trends and tradition, which remains very important to them. They are currently preparing a museum of beer brewing, where visitors will be able to discover the history of this craft and learn more about the brewing process itself.

Need some help?

Fill out the form below

We approach every project individually, with every customer's wish and need in mind. A group of experts from various fields work together to find the best solution for our investor. How can we help you? Fill out our form or call us and tell us about your plans. Together, we'll find the right answer.