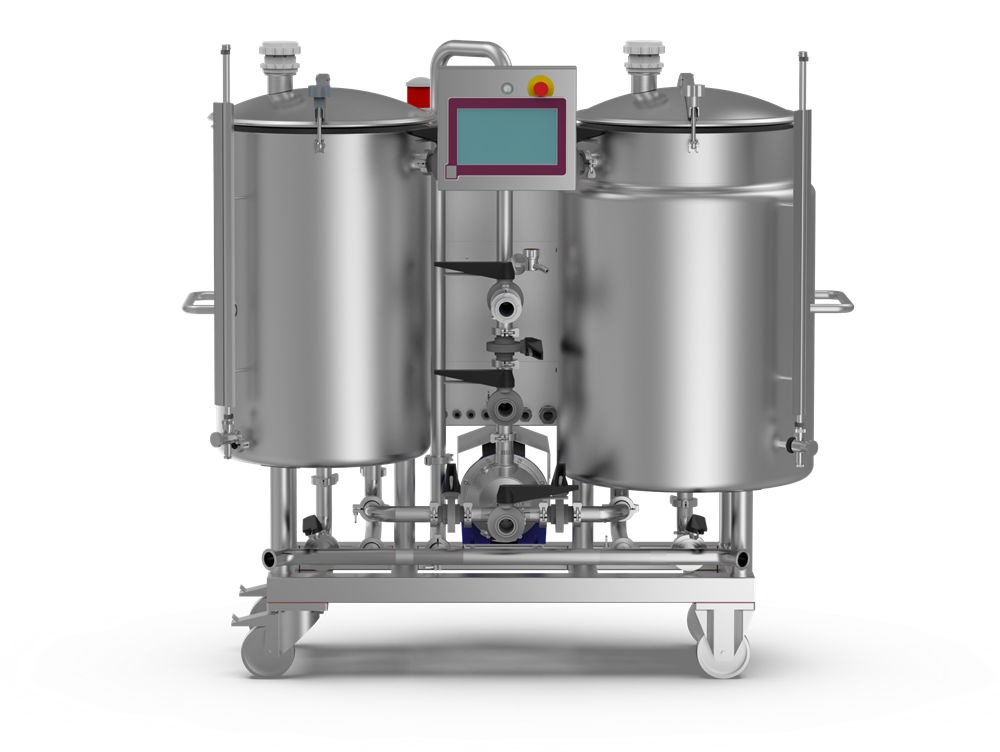

CIP station

Cleaning and disinfection of food production systems

CIP (Clean-In-Place) technology is a standard equipment cleaning and disinfection process used in the food and beverage industry.

The advantage of CIP cleaning is that it enables process equipment cleaning and disinfection without component disassembly, which is why it can also be used to clean hard-to-reach parts of the system where manual cleaning methods are impossible.

CIP station 100 L / 300 L / 500 L

· mobile CIP system for automatic tank, device, and pipe cleaning

· design and production in accordance with EU standards

· versatile use (beer brewing, dairy and beverage industry equipment)

· save water, cleaning agent, and energy

· easy to use

Learn more about CIP technology

- double jacket with insulation

- integrated heaters and level switch

- big top manway with pressure relief valve

- level indicator with engraved scale, plexiglas tube, level indicator tap

- CIP station transport handle

- single jacket, no insulation

- big top manway with pressure relief valve

- level indicator with engraved scale, plexiglas tube, level indicator tap

- CIP station transport handle

- compact support frame made of stainless steel EN 1.4301

- external visible surface is sandblasted with CrNi beads in a sandblasting chamber

- transport wheels: 2 fixed and 2 rotating wheels with brake

- touch screen

- multilingual user interface

- current and set product temperature value display

- pump control

- timer setup

- temperature alarm

- separate (CIP 100)

- with integrated control panel (CIP 300 and CIP 500)

- warning alarm (on top of the cabinet)

- centrifugal pump

- control via central control panel

- stepless flow regulation (variable frequency drive) via control panel

- material: EN 1.4301

- fully established system of inlet, outlet, and fluid circulation tubes

- material: stainless steel EN 1.4301

- integrated butterfly valves for flow regulation

CIP_KOL 2 X 100 L DIN - BR

- Mobile CIP station

- Nominal volume in L: 2 X 100 L

- Use: Cleaning in place

- Pump 0.75 kW, 100-375 l/min

- Total length (L): 1560 mm

- Electrical cabinet 700x500x230 mm

- Heater 6 kW

- Wheels: 2x fixed and 2x rotating (⌀125x45 mm)

- Mains supply voltage: 400 V 50 Hz 3PH

- Acid tank 100 L

- Lye tank 100 L

- Total width (W): 930 mm

- Total height (H): 1470 mm

- Top manway DN500

- Mark: DIN - BR

CIP_KOL 2 X 100 L TC - BR

- Mobile CIP station

- Nominal volume in L: 2 X 100 L

- Use: Cleaning in place

- Pump 0.75 kW, 100-375 l/min

- Total length (L): 1560 mm

- Electrical cabinet 700x500x230 mm

- Heater 6 kW

- Wheels: 2x fixed and 2x rotating (⌀125x45 mm)

- Mains supply voltage: 400 V 50 Hz 3PH

- Acid tank 100 L

- Lye tank 100 L

- Total width (W): 930 mm

- Total height (H): 1470 mm

- Top manway DN500

- Mark: TC - BR

CIP_KOL 2 X 300 L DIN - BR

- Mobile CIP station

- Nominal volume in L: 2 X 300 L

- Use: Cleaning in place

- Pump 1.1 kW, 83-283 l/min

- Total length (L): 1845 mm

- Electrical cabinet 700x500x230 mm

- Heater 12 kW

- Wheels: 2x fixed and 2x rotating (⌀125x45 mm)

- Mains supply voltage: 400 V 50 Hz 3PH

- Acid tank 300 L

- Lye tank 300 L

- Total width (W): 880 mm

- Total height (H): 1970 mm

- Top manway DN420

- Mark: DIN - BR

CIP_KOL 2 X 300 L TC - BR

- Mobile CIP station

- Nominal volume in L: 2 X 300 L

- Use: Cleaning in place

- Pump 1.1 kW, 83-283 l/min

- Total length (L): 1845 mm

- Electrical cabinet 700x500x230 mm

- Heater 12 kW

- Wheels: 2x fixed and 2x rotating (⌀125x45 mm)

- Mains supply voltage: 400 V 50 Hz 3PH

- Acid tank 300 L

- Lye tank 300 L

- Total width (W): 880 mm

- Total height (H): 1970 mm

- Top manway DN420

- Mark: TC - BR

CIP_NOG 2 X 500 L DIN - BR

- CIP station

- Nominal volume in L: 2 X 500 L

- Use: Cleaning in place

- Pump 1.1 kW, 83-283 l/min

- Total length (L): 2085 mm

- Electrical cabinet 700x500x230 mm

- Heater 12 kW

- Mains supply voltage: 400 V 50 Hz 3PH

- Adjustable legs (4x): M16X120, plate ⌀130

- Acid tank 500 L

- Lye tank 500 L

- Total width (W): 980 mm

- Total height (H): 1870 mm

- Top manway DN420

- Mark: DIN - BR

CIP_NOG 2 X 500 L TC - BR

- CIP station

- Nominal volume in L: 2 X 500 L

- Use: Cleaning in place

- Pump 1.1 kW, 83-283 l/min

- Total length (L): 2085 mm

- Electrical cabinet 700x500x230 mm

- Heater 12 kW

- Mains supply voltage: 400 V 50 Hz 3PH

- Adjustable legs (4x): M16X120, plate ⌀130

- Acid tank 500 L

- Lye tank 500 L

- Total width (W): 980 mm

- Total height (H): 1870 mm

- Top manway DN420

- Mark: TC - BR

Green Gold Brewing // Slovenia

Spodnje Grušovlje

Green Gold Brewing is a successful microbrewery from the Savinja Valley, an important hop-growing region in the heart of Slovenia. The brewery is strongly connected to hop growing, as the family's ancestors planted there their first hop plant more than a century ago.

Need some help?

Fill out the form below

We approach every project individually, with every customer's wish and need in mind. A group of experts from various fields work together to find the best solution for our investor. How can we help you? Fill out our form or call us and tell us about your plans. Together, we'll find the right answer.