EN ISO 14122 STANDARD

ISO 14122 is an international standard that is used for stationary and mobile machines where a fixed means of access is required. This standard defines the general requirements for the access to stationary machines and provides guidance on the correct access method when the required access is not possible directly from ground level or from a floor. The standard is divided into 4 parts:

EN ISO 14122-1:2016

Safety of machinery – Permanent means of access to machinery – Part 1: Choice of fixed means and general requirements of access

EN ISO 14122-2:2016

Safety of machinery – Permanent means of access to machinery – Part 2: Working platforms and walkways

EN ISO 14122-3:2016

Safety of machinery – Permanent means of access to machinery – Part 3: Stairs, stepladders and guardrails

EN ISO 14122-4:2016

Safety of machinery – Permanent means of access to machinery – Part 4: Fixed ladders

EN 1090 STANDARD

EN 1090 is a harmonized European standard that regulates the design and production of load-bearing components and structures made of steel or aluminum. The standard has been a requirement in all EU countries since 2014. It defines the requirements for obtaining the FPC certificate and the steel structure CE marking permit.

The standard comprises 3 parts:

EN 1090-1: Execution of steel structures and aluminum structures - Part 1: Requirements for conformity assessment of structural components

This part defines:

- the requirements for the conformity assessment of the internal production control (production process control, production capacity control, internal production control system operation),

- the requirements for the conformity assessment of the structure's components (serial or non-serial production),

- the conditions for issuing the FPC certificate, including the CE mark.

EN 1090-2: Execution of steel structures and aluminum structures - Part 2: Technical requirements for steel structures

This part defines the technical requirements for the production of steel structures, which must be observed in order to ensure a suitable level of mechanical resistance and stability, as well as usability and durability.

EN 1090-3: Execution of steel structures and aluminum structures - Part 3: Technical requirements for aluminum structures

This part defines the technical requirements for the production of aluminum structures.

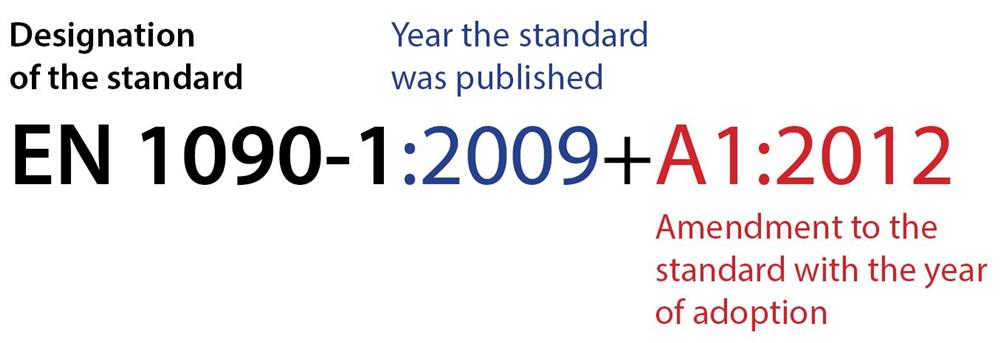

The manufacturer must indicate the version of the standard, according to which the product was manufactured and certified, in the product's technical documentation (certificate, declarations, production documentation).

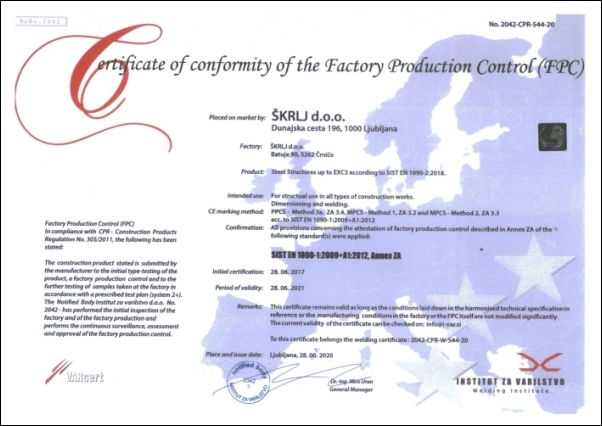

FPC (Factory Production Control) CERTIFICATE

The Factory Production Control Certificate (FPC) is an official document which guarantees that a company's production control system is in accordance with the standard EN 1090-1. This certificate can only be granted by a Notified Body and is mandatory for manufacturers that want to sell metal structures and their components on the European market. Once a manufacturer obtains the FPC certificate, it can affix the CE mark and issue the product's Declaration of Performance.

How can a company obtain the FPC certificate?

The company must submit a request for an FPC certificate to the notified certification body. The notified body shall first carry out an inspection of the production plant and of the internal production control system, and if necessary, prepare a list of required improvements. In order to obtain this certificate, the manufacturer must implement, carry out, and document the internal production control process in accordance with the standard EN 1090-1 and the additional conditions from the standard EN 1090-2 (for steel structures) or EN 1090-3 (for aluminum structures).

Once the manufacturer obtains the FPC certificate, it must maintain a production control system, which has to be carried out in accordance with the defined standards and technical specifications. The notified certification body must carry out regular checks and evaluations of the certified company's production control system.

DECLARATION OF PERFORMANCE

After obtaining the FPC certificate, the manufacturer acquires the right to issue a product's Declaration of Performance and affix the CE mark, thus guaranteeing the conformity of the product.

The Declaration of Performance must include the following information:

- name and full address of the manufacturer,

- serial number,

- product type or identification code of the product type,

- purpose of use,

- system(s) of assessment and verification of constancy of performance,

- applied regulations and standards,

- name of the manufacturer's signatory or their authorized representative,

- notified body and certification mark,

- place and date of issue.

.jpg)

THE DUTIES OF A STEEL STRUCTURE MANUFACTURER

All steel structures and their components must be manufactured in accordance with the relevant standards and the technical documentation. The manufacturer is responsible for the production process control and the final quality control of the product.

The manufacturer must prepare the required technical documentation, which proves the product was manufactured in accordance with the requirements of the EN 1090 standard. The documentation must include, among other things:

- technical drawings of the structure components,

- static calculation of the assembly and its components (stored by the manufacturer),

- instructions for safe use and maintenance,

- warranty statement,

- Declaration of Performance with CE mark.

The technical documentation has to enable material traceability and production process traceability (documented welding processes, welding personnel certificates).

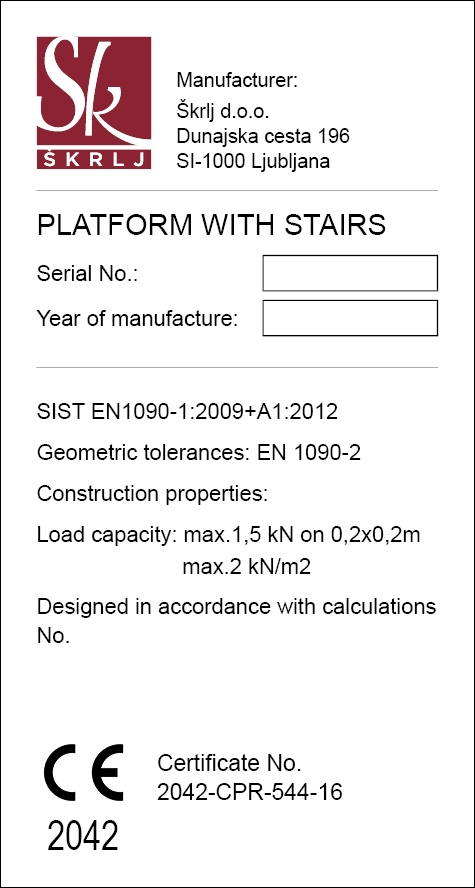

The walking structure must also be equipped with a product identification plate. The plate has to be installed on a visible part of the structure and must contain all the information required by the standard: product name, serial number, year of manufacture, CE mark, applied standards.

WHAT DOES THIS MEAN FOR THE USER?

Why cheaper is not always better

Choosing which equipment to buy can be very difficult as there are many different manufacturers. The price of the product can often be the determining factor, although it can lead to poorer quality. The cheaper product may meet the minimum standard requirements, but the one question that remains is whether it will also meet your expectations. Keep in mind that your walking structure will be used for a long time and it is likely that you, as well as your co-workers and visitors will use it quite frequently. That's why it is important to feel »SAFE« on it.

If you're deciding to purchase a steel structure, make sure that the manufacturer also provides you with the required documentation which ensures that the product complies with the standards and enables you to obtain a use permit. If the documentation is incomplete, you will have to obtain it later, which means there will be additional costs and work. However, in case of improper manufacturing and incomplete material and process traceability you may be unable to ever obtain a use permit.

Škrlj walking structure compared to those made by other manufacturers:

| OTHER PLATFORM | ŠKRLJ PLATFORM |

|

|

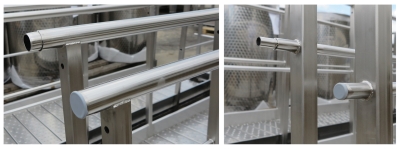

| A removable platform guardrail is less stable. This type of railing is less rigid and less resistant to lateral loads, which means that leaning against it does not feel safe. | The Škrlj guardrail system is much more rigid. The vertical posts are welded to the side of the platform. The horizontal rails and the posts are also welded together. Railing oscillation under side loads is minimal, which gives a feeling of safety and stability when using the platform. |

| A removable guardrail requires more time during assembly and installation at the final location. |

Quick assembly and installation. Platforms are delivered in finished segments – an assembled set of guides, reinforcements, walking gratings and guardrails. The segments are placed onto the support elements, assembled according to the numbered list and screwed together.

|

| Noncontinuous guardrail – there are unprotected parts between guardrail segments. | A continuous connection along the entire length gives the guardrail additional strength. The top rail is made of a stronger pipe profile. |

|

Access to platform by ladder (without guardrail) presents a danger to the user. A safety chain in the access area can't replace a railing as it does not present the same degree of protection. The standard demands a rigid railing.

|

Such solutions are not available with our platforms. |

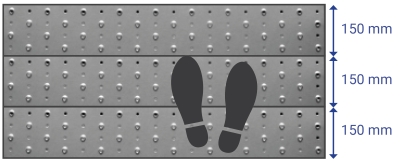

| According to the standard, the walking surface (gratings) must not bend more than 4 mm when a person is walking on it. This is difficult to achieve with a sheet metal grating that is wider than 150 mm. |

The walking gratings on our platforms are 150 mm wide. When walking on the platform, a person always steps on at least two adjacent gratings at a time, which greatly diminishes the bend factor.

|