Brewhouses

The heart of every brewery lies within its brewhouse. This is where a beer gets its unique qualities that play an essential part in developing its final flavor and character. Adaptability, good control, ability to process different mash quantities, creating unique beer styles, coming up with and storing your own recipes - these are the things a craft brewer expects from a brewhouse.

Brewhouses designed by Škrlj d.o.o. provide you with clear and efficient control over the beer brewing process.

Precisely run mash warm up, adding water, soaking and straining the malt, boiling, adding ingredients, cooling down the wort and transferring it into a fermentation tank - all this with only one device.

Choose a brewhouse.

Experiment with different flavors, brew a beer using your favorite quality ingredients. Take a look at our brewhouses and choose the one that would be perfect for you.

- smooth inner surfaces

- separate bottom and jacket heating

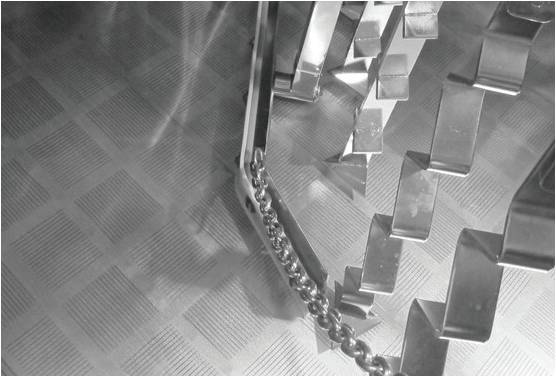

- sieve with conical slots (polished surface)

- integrated agitator: mash rake, removable paddle for spent grain removal

- smooth inner surfaces

- separate bottom and jacket heating

- compact support frame

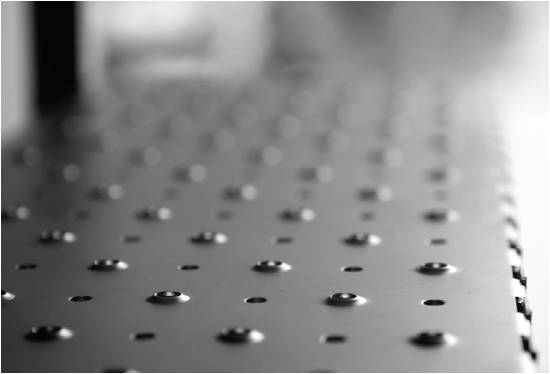

- walking surfaces (stairs, platform) made of perforated anti-slip gratings

- easy access to all workstations and brewhouse connectors

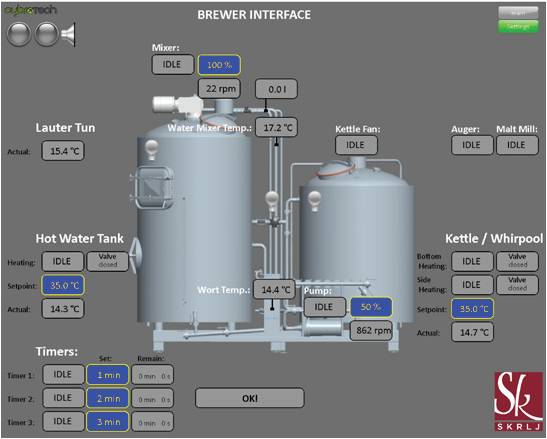

- touch screen

- multilingual user interface

- actual and set value display for integrated devices

- temperature regulation (separate bottom and jacket heating)

- pump and agitator control

- exit wort temperature display

- sparge water volume and temperature display

- timer and alarm setting

- step mashing with set parameters

- manual control valves for wort and water flow regulation

- valve functions are engraved on the pipes

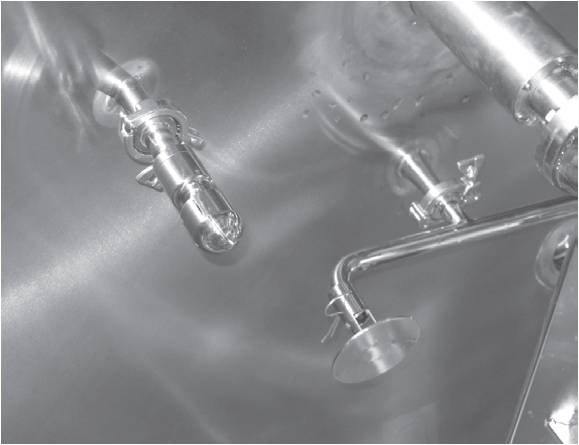

- hygienic design: orbitally welded and polished pipes, TC connections

- single stage (cooling medium: water) or double stage (cooling medium: water and glycol)

- cooling the wort to a temperature that is suitable for starting the fermentation process

- centrifugal sanitary pump for product transfer and CIP cleaning

- product flow is regulated using the control panel

- pipes and connectors for CIP tank cleaning

- all inner tank and pipe surfaces that come into contact with the product are polished

- smooth surfaces enable quick and efficient brewhouse cleaning

Filter by shape

BHM 250L MM/LT K/W EU STEAM

- Compact brewhouse

- Nominal volume: 250L

- Use: Decoction mashing

- Use: Single-step infusion mashing

- Use: Multi-step infusion mashing

- Brewhouse configuration: MM/LT K/W

- Market denomination: EU

- Supply voltage: 400V 50Hz 3PH

BHM 500L MM/LT K/W EU OIL

- Compact brewhouse

- Nominal volume: 500L

- Use: Decoction mashing

- Use: Single-step infusion mashing

- Use: Multi-step infusion mashing

- Brewhouse configuration: MM/LT K/W

- Market denomination: EU

- Supply voltage: 400V 50Hz 3PH

- Type: Single-stage heat exchanger

BHM 500L MM/LT K/W EU STEAM

- Compact brewhouse

- Nominal volume: 500L

- Use: Decoction mashing

- Use: Single-step infusion mashing

- Use: Multi-step infusion mashing

- Brewhouse configuration: MM/LT K/W

- Market denomination: EU

- Supply voltage: 400V 50Hz 3PH

- Type: Single-stage heat exchanger

CT1X 1885 D1270 H1500 0/ATM

- Cold water tank with double jacket

- Nominal volume in l: 1885

- Internal diameter in mm: 1270

- Height H in mm: 1500

- Height Z in mm: 2348

- External diameter [mm]: 1370

- Use: Water preparation

- Min. operating press. [barg]: 0

- Max. operating pressure [barg]: atmospheric

CT1X 2000 D1370 H1410 0/ATM

- Cold water tank with double jacket

- Nominal volume in L: 2000

- Internal diameter in mm: 1370

- External diameter [mm]: 1470

- Height H in mm: 1410

- Height Z in mm: 2270

- Min. operating press. [barg]: 0

- Max. operating pressure [barg]: atmospheric

- Min. operating p. DJ [barg]: 0

- Max. operating p. DJ [barg]: 3

- Min. DJ design p. [barg]: 0

- Supply voltage: 400V 50Hz

- Input power: 0,55 KW

CTXX 4900/40 D1780 H2000 0/ATM

- Cold water tank

- Nominal volume [bbl]: 40

- Nominal volume in l: 4900

- Internal diameter in mm: 1780

- Height H in mm: 2000

- Height Z in mm: 2900

- External diameter [mm]: 1880

- Geometrical volume [l]: 5340

- Use: Water preparation

- Min. operating press. [barg]: 0

- Max. operating pressure [barg]: atmospheric

CTXX 5700 D1900 H2000 0/ATM

- Cold water tank

- Nominal volume in L: 5700

- Internal diameter in mm: 1900

- External diameter [mm]: 2000

- Height H in mm: 2000

- Min. operating press. [barg]: 0

- Max. operating pressure [barg]: atmospheric

- Min. operating p. DJ [barg]: 0

- Max. operating p. DJ [barg]: 3

- Min. DJ design p. [barg]: 0

CTXX 600 D790 H1250 0/ATM

- Cold water tank

- Nominal volume in L: 600

- Internal diameter in mm: 790

- External diameter [mm]: 890

- Height H in mm: 1250

- Min. operating press. [barg]: 0

- Max. operating pressure [barg]: atmospheric

- Min. operating p. DJ [barg]: 0

- Max. operating p. DJ [barg]: 3

- Min. DJ design p. [barg]: 0

- Supply voltage: 400V 50Hz

- Input power: 0,37 KW

MB2 30BBL/40HL MM/LT K/W L-D US

- Microbrewery MB2

- Nominal volume: 30BBL/40HL

- Use: Single-step infusion mashing

- Use: Multi-step infusion mashing

- Brewhouse configuration: MM/LT K/W

- Direction of the process: from left to right

- Market denomination: US

- Supply voltage: 230V 60Hz 3PH

- Type: Single-stage heat exchanger

MB4 15BBL HG/20HL MM LT K W D-L US

- Microbrewery MB4

- Nominal volume: 15BBL HG/20HL

- Use: Single-step infusion mashing

- Use: Multi-step infusion mashing

- Brewhouse configuration: MM LT K W

- Direction of the process: from right to left

- Market denomination: US

- Supply voltage: 230V 60Hz 3PH

- Type: Single-stage heat exchanger

MB4 20BBL/25HL MM LT K W D-L US

- Microbrewery MB4

- Nominal volume: 20BBL/25HL

- Use: Single-step infusion mashing

- Use: Multi-step infusion mashing

- Brewhouse configuration: MM LT K W

- Direction of the process: from right to left

- Market denomination: US

- Supply voltage: 230V 60Hz 3PH

- Type: Single-stage heat exchanger

MB4 30BBL/40HL MM LT K/W1 K/W2 L-D US

- Microbrewery MB4

- Nominal volume: 30BBL/40HL

- Use: Single-step infusion mashing

- Use: Multi-step infusion mashing

- Brewhouse configuration: MM LT K/W1 K/W2

- Direction of the process: from left to right

- Market denomination: US

- Supply voltage: 230V 60Hz 3PH

- Type: Single-stage heat exchanger

- 1

- 2

Pivovarna ZAJC 1725 // Slovenia

Cerkno

Pivovarna ZAJC is an innovative young craft brewery in Reka, a small village near Cerkno. The brewery is a perfect example of how to connect with your community as a business. They work with local restaurant owners and other tourism service providers, and promote the local culinary offer. Their work is a blend of modern brewing trends and tradition, which remains very important to them. They are currently preparing a museum of beer brewing, where visitors will be able to discover the history of this craft and learn more about the brewing process itself.

Need some help?

Fill out the form below

We approach every project individually, with every customer's wish and need in mind. A group of experts from various fields work together to find the best solution for our investor. How can we help you? Fill out our form or call us and tell us about your plans. Together, we'll find the right answer.