The beer production process can be divided into two phases. The first phase, brewing, is performed inside a brewhouse, where a mixture of malt, water, and hops is used to obtain wort. The second phase, fermentation and maturation, is carried out in specially designed tanks (fermenters and maturation tanks). These tanks are used to transform wort into young beer, which then goes through the maturation process in order to obtain the final product - beer.

Inside the brewhouse, the crushed malt (grist) is mixed with hot water, mashed, and lautered. The obtained wort is then boiled; during boiling, brewers add hops and other "spices". Finally, the sediments (trub) must be removed and the wort must then be cooled and pumped into the fermenters. This is a very brief and simplified description of what happens inside the brewhouse. The entire process is actually much more complex and must be run by someone who is knowledgeable about beer brewing and the chemical and physical processes that occur inside the brewhouse.

More about the brewing process

Which process vessels make up the brewhouse?

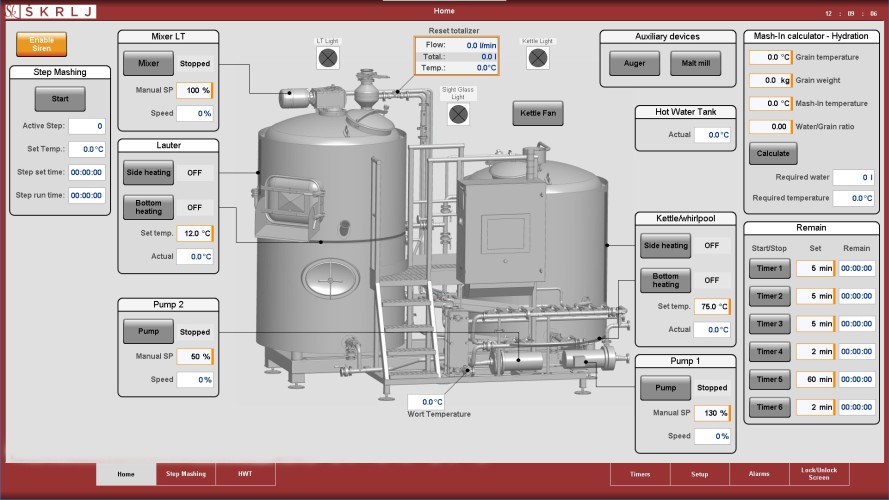

A brewhouse is a set of interconnected process vessels: mash mixer, lauter tun, kettle, and whirlpool. In addition to the process tanks, you also need a hot water preparation tank and a source of uncontaminated (clean) cold water, which will enable smooth workflow. More about water tanks ...

- Copy 2.jpg)

In practice, brewhouses usually have different combinations of process vessels. A brewhouse may have a small number of combined vessels (mash mixer-lauter tun, kettle-whirlpool), or it may consist of a set of separate tanks, each one used to carry out a specific process.

Craft brewers often pick a two-vessel brewhouse with:

mash mixer / lauter tun + kettle / whirlpool

What functions must the brewhouse enable?

Temperature regulation

Accurate temperature measurement and the duration of each phase of the brewing process are crucial for the quality of the final product. The brewhouse must have a suitable number of heating surfaces (pillow plate), which enable you to quickly achieve and maintain the desired product temperature.

More about temperature regulation ...

Mash mixing

The mash must be continuously mixed during heating. Therefore, the mash mixer/lauter tun must be equipped with an agitator. Continuous mixing prevents product overheating at the bottom of the tank and improves mash homogeneity, which means the temperature of the mash is more homogeneous and the mash itself is more evenly hydrated. Such an environment creates the perfect conditions for a select group of enzymes to start breaking down the components in the malt before the mash temperature increases to the point where they become inactive and other types of enzymes continue this process.

Opinions on optimal enzyme activity temperatures vary among brewers. However, the mash temperature should definitely not exceed 78 °C (172.4 °F). Starch that is released at higher temperatures can no longer be broken down and can develop an unpleasant taste in the final product.

Product flow regulation between tanks and process devices

A well-designed system of pipe connections, control valves, and pumps facilitates the brewer's work. Manual pipe switching between tanks is not necessary. You have to simply open the suitable valves and activate the pump to start the selected process (sparging, filtering, wort cooling, pumping between tanks).

Automated operation

Process automation can save you a lot of trouble. It is recommended that the brewhouse enable step programming for step mashing, controlled water addition, warning timer setup, and storage of tested recipes which would ensure brewing process repeatability.

Simple cleaning

Regular brewhouse and equipment cleaning is essential if you want to make high-quality beer without a bad aftertaste. Coatings accumulate on the walls of the tanks and of the heat exchanger, which can reduce heat transfer and have a bad effect on the taste of the product. The internal surfaces of all Škrlj brewhouse tanks and pipes that come into contact with the product during work are polished. Smooth surfaces enable quick and efficient system rinsing.

Smaller mobile two-vessel CIP stations are very convenient. The two tanks are used to prepare the surface cleaning and disinfection solutions. The CIP station can be used to clean the tanks, heat exchanger, pipes, and valves by pumping the solutions through the system. The tanks must be equipped with a CIP spray ball.

What is a "compact brewhouse"?

A compact brewhouse is a system of process tanks and devices a brewer needs to carry out the entire brewing process, from mashing to the transfer of wort into the fermenters. The tanks are mounted on a compact support frame, while the larger models are connected by a platform (walkway) and staircase. The platform provides easy access to all work surfaces, doors, and connectors on the tanks.

What are the advantages of a compact brewhouse?

- fewer tanks (better price)

- less space required for installation

- can be used to perform different mashing processes (single infusion mashing, step mashing, decoction mashing)

- flexibility (also suitable for processing small quantities of mash, trying different recipes, experimenting with new flavors)

- quick production start (the piping system and electrical wiring are set up before delivery, which means the brewhouse can be installed very quickly and you can start brewing almost immediately).

Take a look at our wide range of brewhouses. Use filters to sort the products.

SELECT A BREWHOUSE