Since 1967

Tradition & quality

Škrlj d.o.o. was built on the solid foundations of rich family tradition and has become a valued European company with an established international market. The company's core activities are the development, production, and sale of stainless steel equipment for the food, pharmaceutical, and chemical industries.

We have the experience, modern technology, and necessary knowledge for first-class stainless steel processing.

High quality. Adaptability. Innovation. This is what convinced our customers.

News & Announcements

Go behind the scenes

Christmas and New Year

21 November 2025Office closed from December 24, 2025, to January 4, 2026 We would like to inform you that the company will be closed during the holiday season starting Wednesday, December 24, 2025. Work will resume on Monday, January 5,...

Introducing LUXORIA Whirlpools and Pools

18 November 2024We're excited to announce our offer now includes a new product line - Luxoria whirlpools and pools! They are available in various shapes, sizes, and configurations, and are perfect for wellness centers, swimming facilities,...

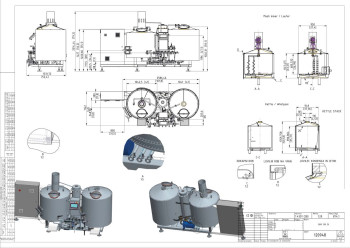

Exciting Improvements to Our Pneumatic Wine Presses

06 November 2024We are thrilled to announce a series of significant enhancements to our pneumatic wine presses, aimed at improving efficiency, cleanliness, and juice extraction quality. Here's a closer look at the changes: Panel Drainage...

Drop&Weld - congratulations

13 September 2024Drop&Weld - napredni strojni vid za zeleno transformacijo procesov varjenja v tovarnah prihodnosti Čestitke ekipi za osvojeno srebrno priznanje za inovacijo Drop&Weld, nacionalno priznanje, ki ga je v okviru Dneva...

Custom cabinets for presses

09 April 2024We've partnered up with RITTAL, a leading global supplier of enclosure systems, automation and infrastructure with its industrial, IT, energy and power, cooling and service units, and successfully made our first "custom...

Transition to B&R automation technology

12 February 2024In 2023, we transitioned to using B&R controllers and panels for our products, equipped with a touch screen. One of the main reasons for this change was the exceptional quality of their products. B&R controllers also enable...

Documentation & orders

Quick and easy access to your order documentation

Product documentation

Your product documentation can be accessed online! Obtaining your documents is now quick and easy, the only thing you need is the product’s serial number

Learn more about product documentation...

Your product documentation

Offers & orders

We provide our registered B2B partners with simple online access to all their offers and orders, current and past.

Learn more about the benefits of offer and order online access...

YOUR OFFERS AND ORDERSCareer opportunities

Join our team

Metal forming and cutting operative (machine operator) - M/F

12 December 2024ABOUT US Škrlj d.o.o. is a family-owned company with a rich tradition dating back to 1967. Today, we specialize in designing and manufacturing high-quality stainless steel equipment for the beverage, food, pharmaceutical,...

Metal forming and cutting operative (locksmith, metalworker) - M/F

19 November 2024ABOUT US Škrlj d.o.o. is a family-owned company with a rich tradition dating back to 1967. Today, we specialize in designing and manufacturing high-quality stainless steel equipment for the beverage, food, pharmaceutical,...

Metal forming and welding operative (welder) - M/F

19 November 2024ABOUT US Škrlj d.o.o. is a family-owned company with a rich tradition dating back to 1967. Today, we specialize in designing and manufacturing high-quality stainless steel equipment for the beverage, food, pharmaceutical,...