Open pressing system

Half of the press drum is perforated, while the other is covered by an impermeable membrane. An integrated compressor is used to establish the desired pressure within the press drum, which inflates the membrane and, consequently, starts pressing the grape mass and draining the must. Must then flows through the perforated half of the drum into a collection pan. Soft grape or grape pomace membrane pressing prevents any mechanical damage to the grapes, which ensures a production of high-quality must and wine.

Advantage: large draining surface.

Drum capacities: drum volumes range between 500 and 5500 L.

Advantage: large draining surface.

Drum capacities: drum volumes range between 500 and 5500 L.

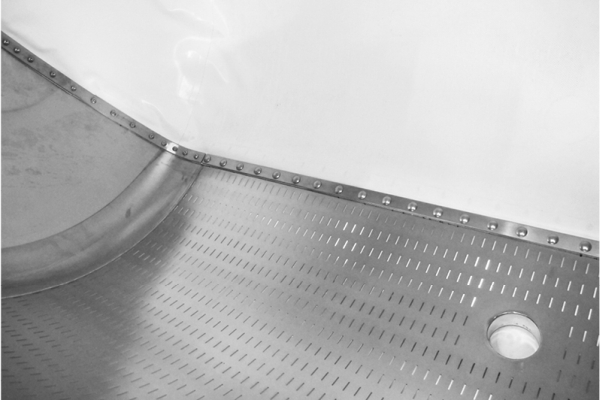

Electropolished drum

All presses up to size PSP 16 (1600 liters) have an electropolished drum in their standard design.

Advantages of an electropolished drum:

- reduced grape pomace sticking to the drum surface, which means better must flow through the drainage holes,

- easier drum cleaning,

- reduced water consumption,

- reduced possibility of coating,

- increased corrosion resistance.

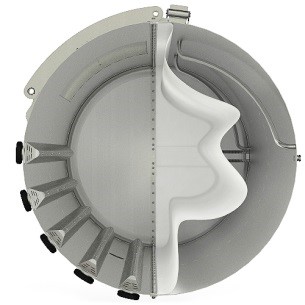

Closed pressing system

Half of the press drum is covered by an impermeable membrane, while there are perforated drain channels all along the other half. An integrated compressor is used to establish the desired pressure within the press drum, which inflates the membrane and, consequently, starts pressing the grape mass and draining the must. Must then flows through drainage openings into a collection pan. Soft grape or grape pomace membrane pressing prevents any mechanical damage to the grapes, which ensures a production of high-quality must and wine.

Grape presses with a closed pressing system can also be used for grape pomace fermentation and maceration in the drum. In this case, it is recommended that the press drum is also equipped with a cooling jacket (pillow plate).

Advantage: reduced possibility of must oxidation.

Drum capacities: drum volumes range between 500 and 20,000 L.

Grape presses with a closed pressing system can also be used for grape pomace fermentation and maceration in the drum. In this case, it is recommended that the press drum is also equipped with a cooling jacket (pillow plate).

Advantage: reduced possibility of must oxidation.

Drum capacities: drum volumes range between 500 and 20,000 L.

Electropolished drain channels

All drain channels are electropolished. Advantages of an electropolished surface:

- reduced grape pomace sticking to the drum surface, which means better must flow through the drainage holes,

- easier drum cleaning, reduced water consumption,

- glossy and shiny surface,

- reduced possibility of coating,

- increased corrosion resistance.

Closed pressing system with possibility of hyperreductive pressing

Half of the press drum is covered by an impermeable membrane, while there are perforated drain channels all along the other half. The drain channels form a connected web, which creates a larger draining surface.

The PSH press combines two pressing systems. It can be used for classic or hyperreductive pressing. Depending on grape quality and variety, the winemaker can decide which pressing system to use. Switching from one system to the other is quick and easy.

The PSH press combines two pressing systems. It can be used for classic or hyperreductive pressing. Depending on grape quality and variety, the winemaker can decide which pressing system to use. Switching from one system to the other is quick and easy.

Learn more about the hyperreductive technology

The drain channels are electropolished, which makes press maintenance much easier.