A plate heat exchanger is composed of multiple profiled stainless steel plates which are connected to each other. The plates are mounted on special support shafts and fixed onto a compact stainless steel frame (painted or not). The product and the cooling medium (cold water or glycol) flow through the plates on separate flow paths in opposite directions.

The heat exchangers most suitable for use in the beer brewing industry are made of stainless steel. Stainless steel is a corrosion resistant material that, if cleaned regularly, does not require special and/or additional maintenance. Stainless steel plates enable good heat transfer between media, without major heat loss.

What does a heat exchanger do?

The purpose of a heat exchanger is to lower the temperature of the wort while it is being transferred from the kettle to the fermenter. The wort temperature must decrease until it reaches a value that is suitable to start the fermentation process. After it's been boiled, the wort must flow through the plate heat exchanger in the opposite direction of the cooling medium. Consequently, the wort temperature gradually decreases, while the cooling medium temperature increases.

Choosing the right heat exchanger

Škrlj brewhouses are equipped with high-quality heat exchangers. All components that come into contact with the beer during the work process are made of AISI 316 stainless steel.

Our offer includes heat exchangers with single-stage or two-stage cooling systems.

Single-stage heat exchanger

During cooling with a single-stage heat exchanger, the only cooling medium used is cold water.

The wort enters the plate heat exchanger at a temperature of approximately 100 °C. Due to the interaction between the hot wort and the cold water inside the heat exchanger, the wort temperature gradually decreases, while the water temperature increases.

Using water that has been cooled to a temperature of 13 °C, you can ensure efficient wort cooling as shown in the table below:

Brewhouse mini BHM 250L / BHM 500L

| wort cooling | 100 °C to 18 °C | 212 °F to 64.4 °F |

| water heating | 13 °C to 85 °C | 55.4 °F to 185 °F |

Our advice

The use of a single-stage heat exchanger is suitable:

- if you have a source of sufficiently cold water (cooled to at least 13 °C),

- if cooling with cold water can lower the wort temperature to the value, required for the purposes of the brewing process.

Škrlj's brewhouse mini (BHM 250 and BHM 500) basic model designs include a single-stage heat exchanger. In case of a two-stage heat exchanger, the design is slightly modified, as it requires different pipe connections and additional glycol connectors.

Two-stage heat exchanger

During cooling with a two-stage heat exchanger, the cooling media used are cold water and glycol.

Cooling is carried out in two stages: in the first part of the exchanger, the wort is cooled with water, while in the second part, cooling is carried out using glycol.

Brewhouse mini BHM 250L / BHM 500L

| STAGE 1 - cooling with water | ||

| wort cooling | 100 °C to 20 °C | 212 °F to 68 °F |

| water heating | 13 °C to 83 °C | 55.4 °F to 181.4 °F |

| STAGE 2 - cooling with glycol | ||

| wort cooling | 20 °C to 7°C | 68 °F to 44.6 °F |

| glycol heating | 1 °C to 13 °C | 33.8 °F to 55.4 °F |

Brewhouse BH 10hl / 20hl / 25hl

| STAGE 1 - cooling with water | ||

| wort cooling | 100 °C to 30 °C | 212 °F to 86 °F |

| water heating | 21 °C to 80 °C | 69.8 °F to 176 °F |

| STAGE 2 - cooling with glycol | ||

| wort cooling | 30 °C to 13°C | 86 °F to 55.4 °F |

| glycol heating | 1 °C to 14 °C | 33.8 °F to 57.2 °F |

Our advice

The use of a two-stage heat exchanger is suitable if the brewing process requires lower wort temperatures that cannot be achieved only with the use of cold water.

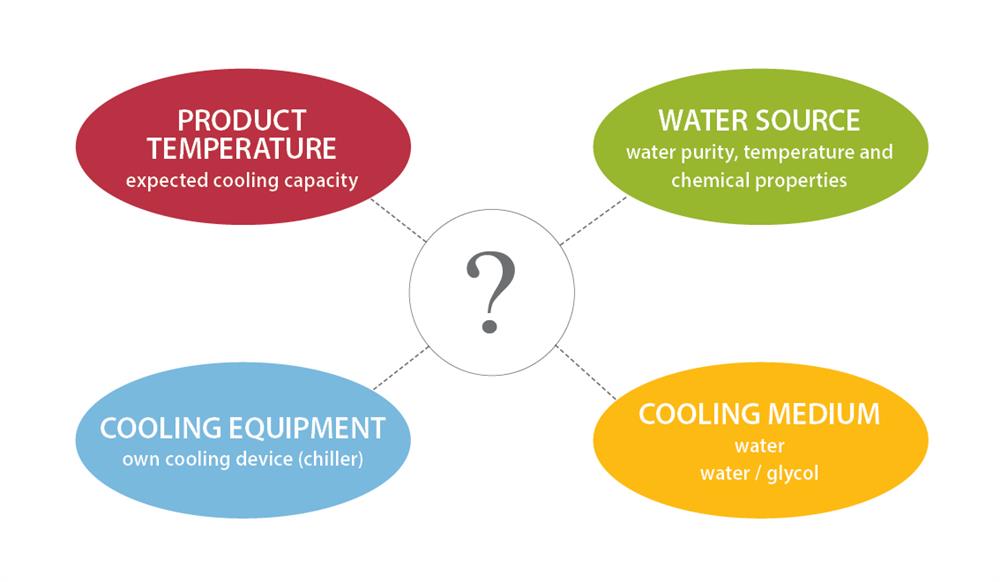

Important information to obtain before a purchase

- What is your water quality like? Find information on water purity, temperature and chemical properties.

- Do you plan on installing your own water cooling system (cold water tank, chiller)?

- What kind of beer do you plan on brewing? What temperature values does your brewing process require?

- Are you thinking of purchasing a brewhouse system complete with a hot water and a cold water tank? This would enable simple water flow and temperature control using the main control panel.

Consult a cooling system expert. A well-thought-out plan can be of great help to the equipment manufacturer in designing a system that will be perfectly adapted to your way of working.

See also: