Mashing and mixing system

Malt is germinated grain that is used for beer brewing and for the distillation of various spirits (e.g., whiskey). In order to obtain the desired components from the malt, the milled malt (grist) must be mixed with hot water – this process is called mashing. The water and malt mixture (mash) in the mash tun is gradually heated in order to create optimal conditions for the activation of enzymes that break down the starch and convert it to fermentable sugars, which are transformed into alcohol during the fermentation process.

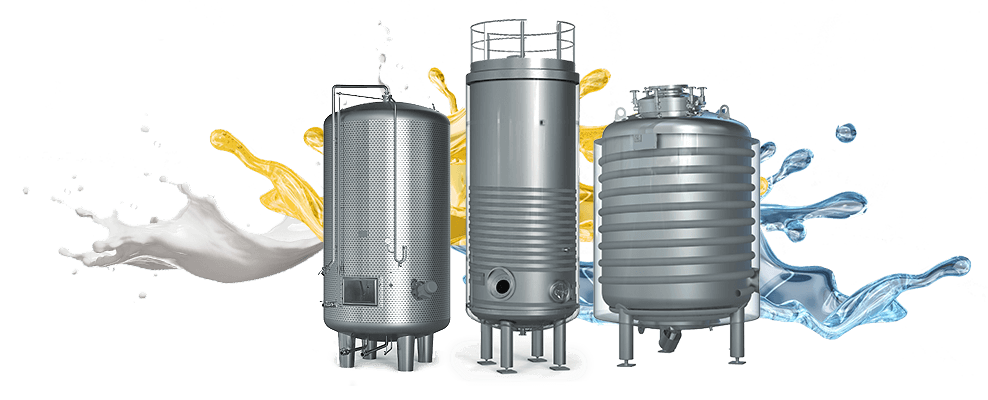

The MM/LT-HWT system consists of two tanks: the mash mixer/lauter tun and the hot water tank, which are connected by a walking platform. This system enables programmed infusion mashing (i.e., step mashing) in multiple steps. Each step must have a defined target temperature, step time and mash mixing intensity. The tanks and the integrated devices are controlled via the touch screen control panel.

Mash mixer – lauter tun (MM/LT)

The tank bottom and jacket are equipped with heating zones and insulated with stone wool. System heating is carried out using steam. Heating in the bottom and jacket areas can be regulated separately.

The hot water tank WTXU 5700 L is designed to prepare and store the hot water, used during the mashing process. The tank bottom and jacket are equipped with heating elements (steam heating) and insulated with stone wool.

The stainless steel platform and stairs are designed and manufactured in accordance with the EU standards for the manufacture of walking structures. The platform enables easy access to the control panel and facilitates process control.

This product and its software are designed, developed, and produced entirely by SK Škrlj.