All our work is performed in accordance with strict European quality standards. High quality has always been our main priority, which has also helped us enter and solidify our place on established international markets.

High-quality stainless steel

Consistent quality without compromise is the main priority for every manufacturer, including SK Škrlj. Our extraction systems are manufactured by carefully combining innovative technological solutions and state-of-the-art production processes with highly specialized equipment and certified materials from reputable suppliers. Our success is not merely a consequence of modern technology and years of experience, but also the result of our team’s continuous thirst for knowledge, which enables us to discover and master new specialized processes in the field of stainless steel processing.

In case of high pressure and temperature loads, high-alloy stainless materials, which are also used in the construction of pipe connections, are extremely important in order to ensure safety and high anticorrosion resistance. Steels are alloyed mainly to improve their mechanical properties, while an increased hardenability also improves their heat treatment ability. Austenitic-ferritic or duplex stainless steels have high elongation properties and provide better corrosion resistance. This helps prevent material damage, and defects on the surface and the structure itself in case of long-term loads. Our extraction systems are made of high-quality stainless steel (EN 1.4301, 1. 4404, 1.4418, 1.4571, 1.4435). Other components that we do not manufacture ourselves are all made by reputable suppliers.

Pump without servicing

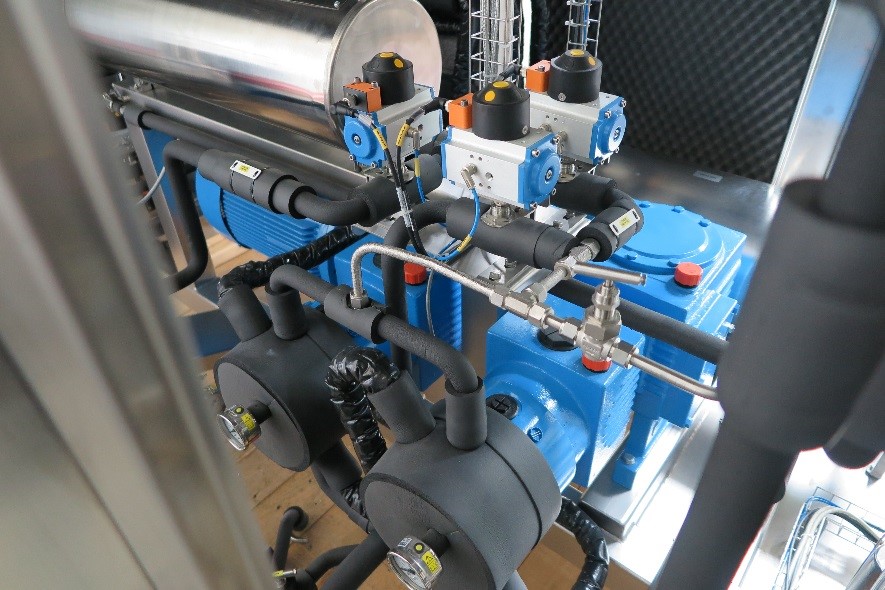

Our systems are equipped with membrane pumps made by Lewa Nikkiso, the world's leading pump manufacturer. One of their most important characteristics is that they ensure complete inertness when in contact with various samples, as the contact materials are made of stainless steel and Teflon (PTFE). These pumps are robust and extremely reliable, which is why they are one of the most flexible and simple pumping solutions, and thus perfect for use with a wide range of liquids. Due to their robust structure (pump with capacity 200 kg/h weighs 700 kg) they are most often used in petrochemistry and on oil rigs, where extreme work conditions are common due to contact with highly corrosive substances and constant exposure to a salty atmosphere. The exceptional properties of these pumps were what ultimately tipped the scales for us, as they ensure reliable pump operation with supercritical fluids at low maintenance costs.

Pump with Teflon (PTFE) membrane

Apart from its resistance to most chemicals, this material is also highly inert, which makes it ideal as it does not leave any residue in the extracts.