Nous sommes ravis d'annoncer une série d'améliorations importantes apportées à nos pressoirs pneumatiques, visant à faciliter le nettoyage et à améliorer l'efficacité et la qualité de l'extraction du jus. Voici un aperçu des changements :

Panneau de drainage (modèles PST)

Nos pressoirs à tambour fermé sont désormais équipés de grands panneaux de drainage électropolis. La conception ondulée interconnectée des panneaux permet une augmentation de 50 % de la surface de drainage et une augmentation de 100 % des perforations de drainage par rapport aux canaux de drainage des tambours fermés ordinaires.

De plus, la conception unique avec ouverture à charnière permet un nettoyage simple et efficace du pressoir sans entrer dans le tambour ni retirer le panneau de drainage.

Remplissage axial excentrique (modèles PST)

Tambours électropolis (modèles PSP)

Tous les tambours de pressoir ouverts de la série M (tailles de 5 à 16 HL) sont désormais électropolis. Avec l'électropolissage du tambour perforé, on obtient une surface extrêmement lisse et propre, réduisant considérablement le temps de nettoyage.

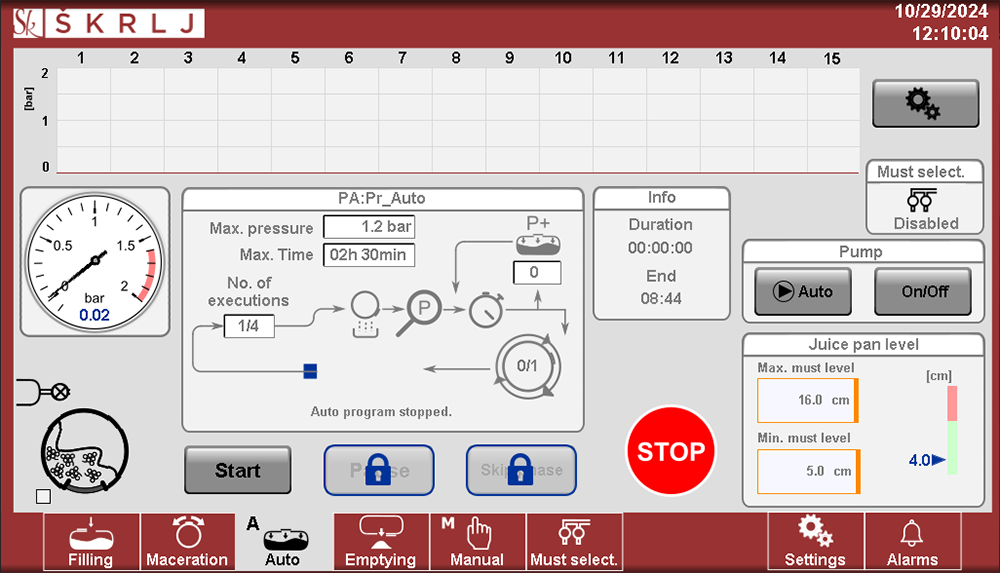

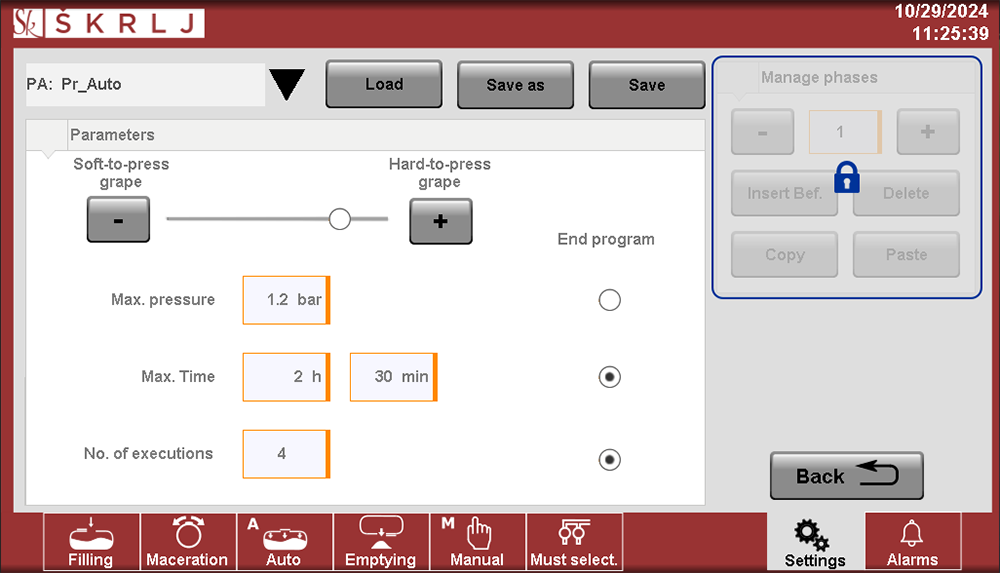

Programme de pressurage auto-optimisant (modèles PSP, PST, PSC – avec commande automatique ABR)

Notre nouveau programme de pressurage permet le contrôle constant du débit du jus, avec une gestion précise de la pression et de l'émiettage. Cette solution permet une extraction optimale du jus avec un cycle de pressurage plus court.

La capacité d'auto-optimisation du programme de pressurage permet des augmentations de pression et une gestion d'émiettage basées uniquement sur les valeurs mesurées et les critères de l'opérateur (qualité, rendement, temps de pressurage etc.).

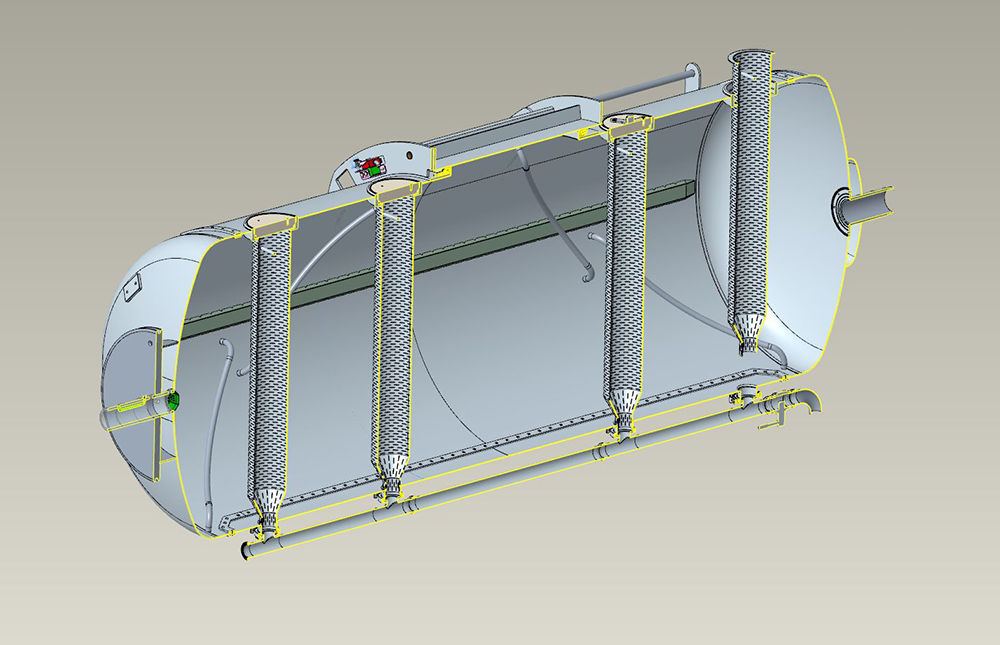

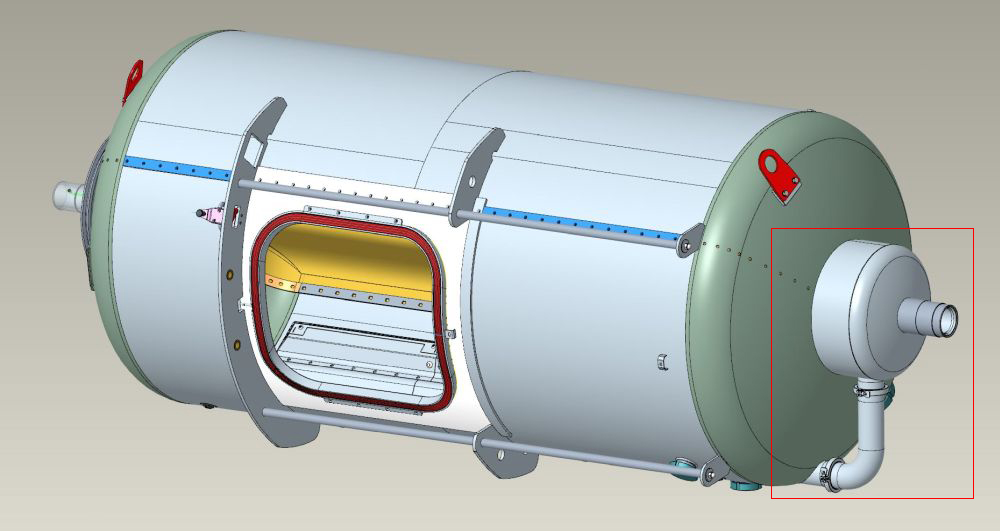

PSC – Pressoir à drainage central

Conçu spécifiquement pour les variétés de raisin difficiles à presser, notre tambour de pressoir PSC comprend des drains cylindriques centraux (verticaux) et une double membrane.

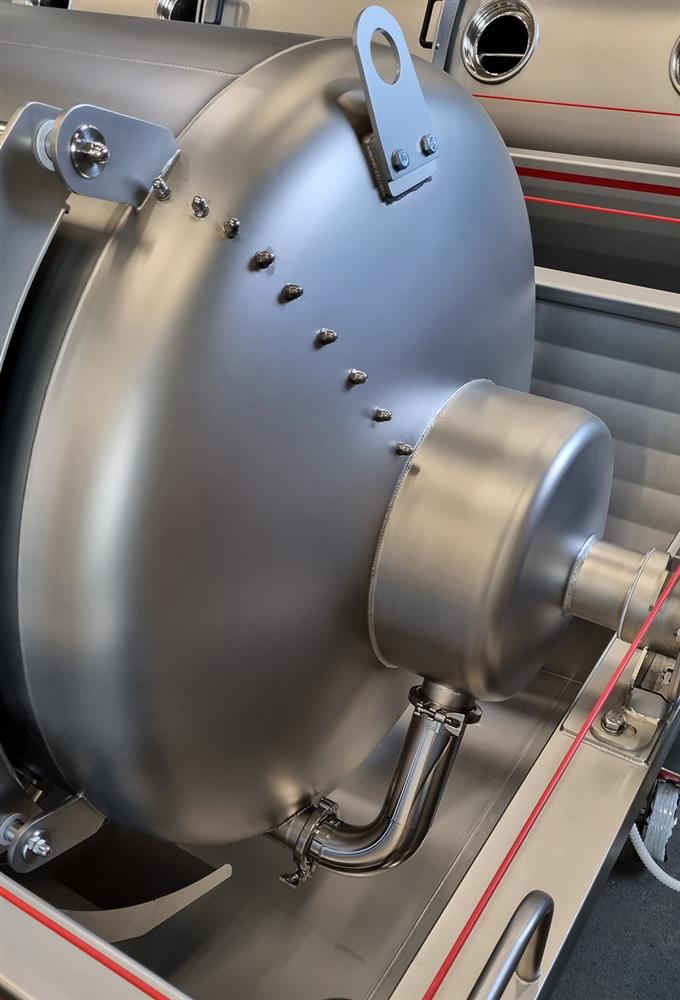

La position centrale des drains réduit de moitié la distance entre la surface de drainage et la membrane exerçant la pression. Les drains cylindriques électropolis permettent un démontage facile et offrent une surface lisse et facile à nettoyer.

Ensuite, tout le jus est dirigé vers un tuyau électropoli et transféré dans le bac de réception.