A guide for buyers and sellers

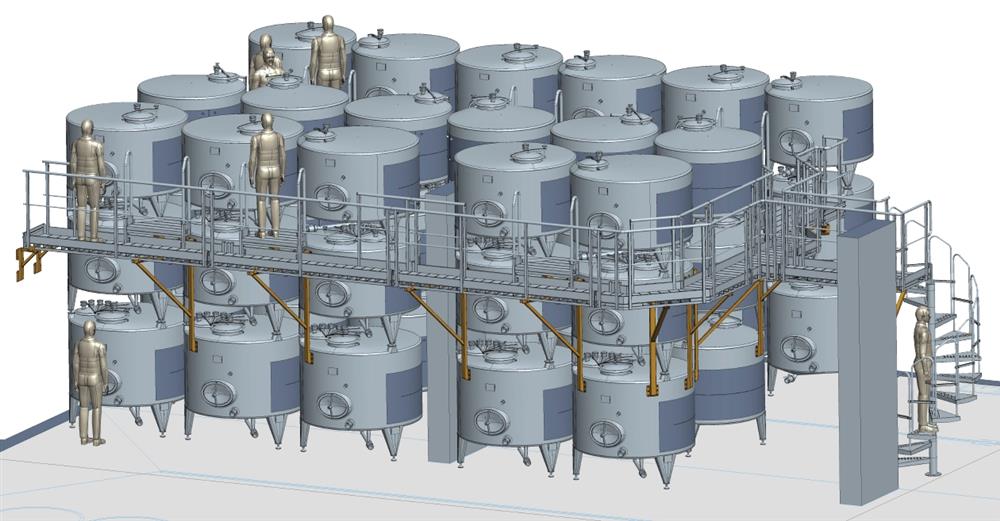

There's more to planning a winery layout than simply choosing tanks with suitable capacities. The main goal is to create a functional space that will encourage creativity and where you will be happy to work and welcome your guests. This means that a winery should have enough work space, easy access to all work areas, and a pleasant atmosphere.

Škrlj can help you achieve this. Our experienced engineers, technologists, and sales team have joined forces and prepared a guide with practical tips on how to arrange equipment in your winery. When preparing this guide, we focused mainly on wine production facilities, but most of the advice can also apply to breweries and other food processing plants.

Take a look at our practical advice and make note of everything you need to bear in mind when deciding where to place each piece of equipment.

Let's begin with the basics

Browse through our range of standard products

Take a look at our standard tanks, platforms, staircases … Our standard elements enable faster deliveries and more affordable options.

Standard platforms and staircases

Follow the principle “simple and functional”

When equipping the work areas where the production processes will be carried out, there are many factors to keep in mind. There is usually a lot of mechanical equipment in a winery and the layout must ensure a smooth, fluid, and logical work process.

Ergonomics, functionality and energy efficiency should be the focal points during planning.

Clear placement details reduce the possibility of errors and get superior results

Based on our years of experience, we know that projects with clearly defined goals early in the planning process are realized faster and at lower costs. That is why we recommend that you provide us with as much useful information as possible (winery layout, technical drawings, photographs) and tell us all your wishes regarding the placement before the start of the planning process.

![]() Hint: Send us photos of the space (winery) and of all prominent objects. Make sure you send photos of suitable size and quality. Multiple photos or other large documents can be sent using WeTransfer, Dropbox or Google Drive.

Hint: Send us photos of the space (winery) and of all prominent objects. Make sure you send photos of suitable size and quality. Multiple photos or other large documents can be sent using WeTransfer, Dropbox or Google Drive.

![]() Hint: Let's take advantage of modern communication tools. Video calls, for example, can be an easier as well as more efficient way for customers to express their demands and for us to present our suggestions.

Hint: Let's take advantage of modern communication tools. Video calls, for example, can be an easier as well as more efficient way for customers to express their demands and for us to present our suggestions.

Structural requirements

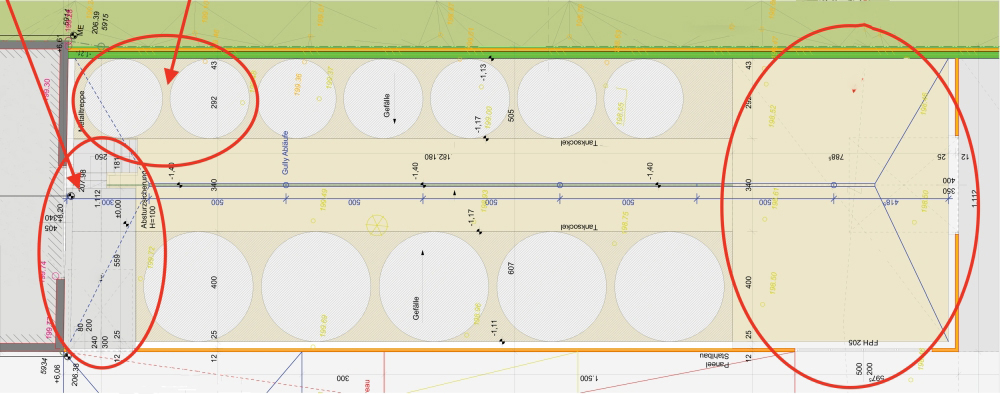

Room dimensions, floor slope and slope direction

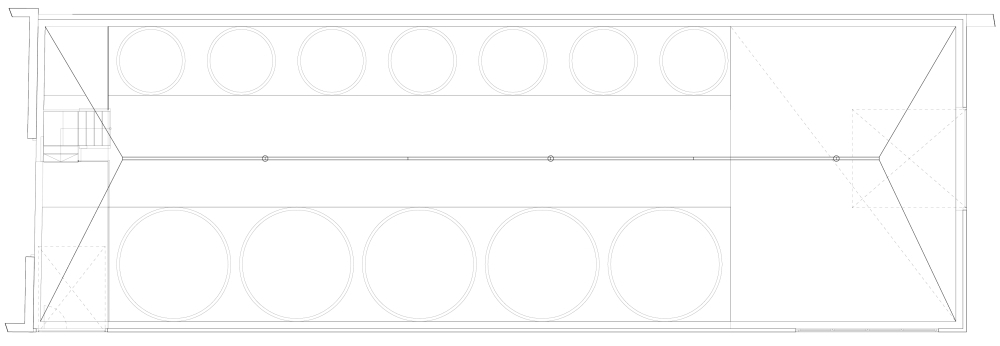

You must provide us with the dimensions of the room along with all other important details.If it's a smaller project, a simple hand drawing, a drawing made with a template or on the computer using special software will suffice. The floor slope and the slope direction must be indicated on the drawing. If tanks are installed on floors with smaller slopes, they can be levelled using their height-adjustable legs.

![]() Hint: If you send us project drawings of the new premises (DWG format), it would be very helpful if, in addition to the detailed version, you also send us a cleaned up version, which contains only the information that is important for equipment placement. Such a drawing can be prepared by your design/project engineer.

Hint: If you send us project drawings of the new premises (DWG format), it would be very helpful if, in addition to the detailed version, you also send us a cleaned up version, which contains only the information that is important for equipment placement. Such a drawing can be prepared by your design/project engineer.

Example of a detailed project drawing:

Example of a cleaned up project drawing:

Access

The position and dimensions (width x height) of the door, through which the equipment will be brought into the room, must be clearly marked on the drawing. If the premises where the tanks will be installed are already built, check the dimensions of the entrances. Make sure the tanks you selected will be able to pass through the doors and don’t forget to take into account both the tank perimeter and the installed equipment.

It is different if the tanks are installed before the construction work is completed. In this case, we need to know the planned time frame for the production and delivery of the tanks and other equipment in order to coordinate it with the construction work plan.

Passageways and transport areas

If there are any transport areas or passageways to other parts of the facility, which must remain clear, mark them on the drawing.

Preexisting architectural elements

Are there any architectural elements in the room (columns, beams, windows etc.) which could affect the placement of the equipment and which must be taken into account when planning?

Mechanical and electrical installations

Provide us with the information on all existing and planned installations. Electrical installations, piping, ventilation, planned cooling system - these are all elements that need to be considered when planning the layout.

Equipment placement

Determine the approximate number and types of tanks, the desired capacity

| 1) Which grape varieties do you have and in what quantities? | ||

| 2) How many must and wine storage tanks will you need (total capacity and quantity)? | ||

| 3) Which tank types would you choose: cylindrical, rectangular, stackable …? | ||

| 4) Do you plan to further expand your business in the future? If yes, then you should plan ahead and leave some space in the winery to accommodate additional tanks. | ||

| 5) Which of your requirements are nonnegotiable and where would you allow us to make some adjustments?? |

Preexisting tanks

| 1) Are there any preexisting tanks? Send us their dimensions and exact placement. | ||

| 2) Is it possible to move these tanks? | ||

| 3) Do the characteristics of the old tanks (e.g., position of doors and connectors) also need to be replicated on the new ones in order to achieve a uniform appearance? |

Recommended gap between adjacent tanks - 100 mm

When a tank is full, the tank jacket bulges slightly due to fluid pressure, especially if the tank has a higher jacket. Therefore, the distance between adjacent tanks should be at least 100 mm, a fact that must be taken into account when planning.

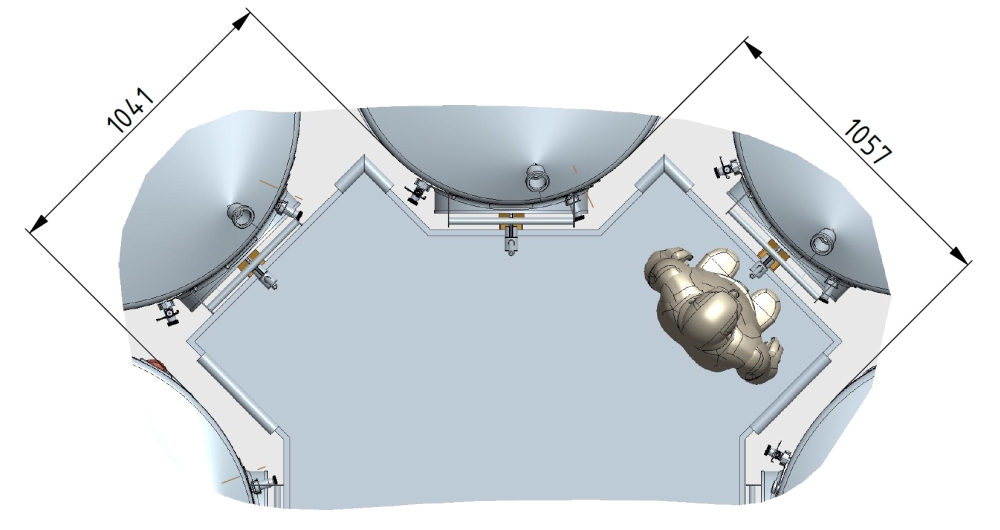

Avoid angular tank placement

By placing the tank in a corner, the space will be used very efficiently, but if this tank is flanked by two others, it can present a construction problem. In fact, if a tank is placed in a corner, the required maneuvering space for the installation of tank connections (doors, drains …) is greatly reduced. A nonfunctional placement of the tank fittings makes work difficult and can be a problem when opening doors and connecting tanks to external devices.

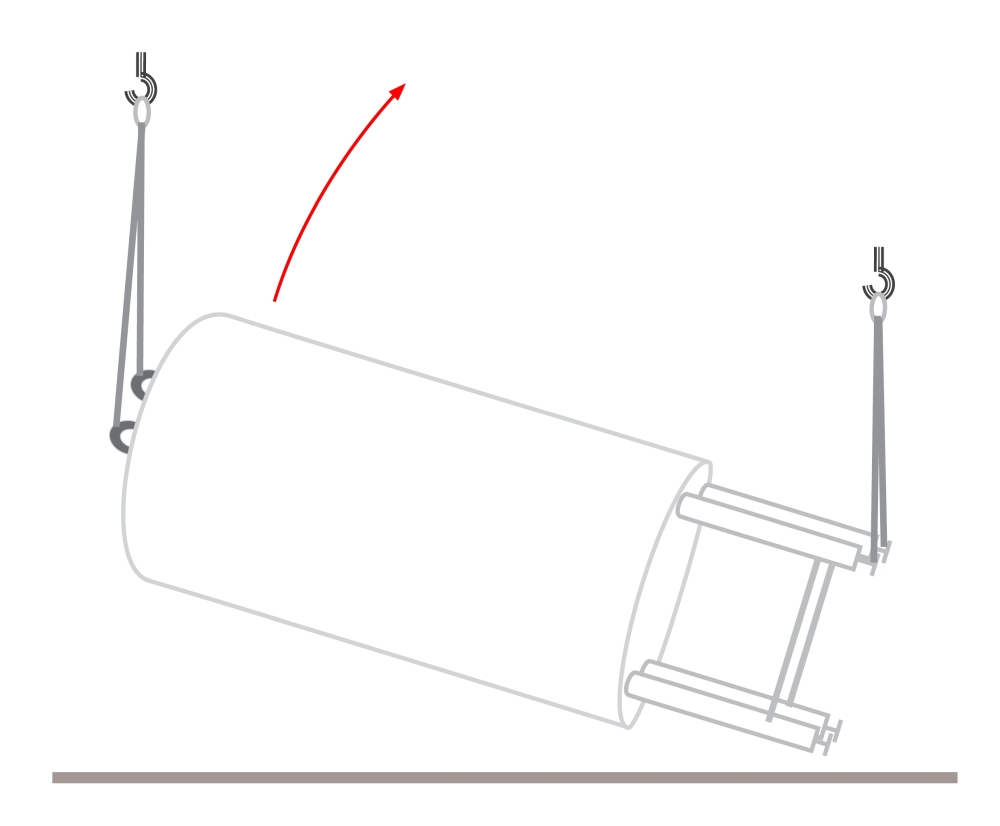

Move tanks into vertical position

Once a tank is brought into the room, the work is not done yet. The tank must then be lifted from horizontal into vertical position, which means the room (ceiling) must also be high enough to do that. As each tank is added to the room, the maneuvering space decreases. The layout must be planned so that there is enough space to place each of the tanks, first to last, in their final position.

Big enough work area

Consider what kind of work will be carried out in the room (fermentation, transfer, filtration ...). You have to not only enable access to all tank connectors, but also provide enough space for the machines and other accessories that will be needed to carry out the work.

Will you also need the maneuvering space to access the tanks with a forklift or a hand truck?

Access to tank lid connectors

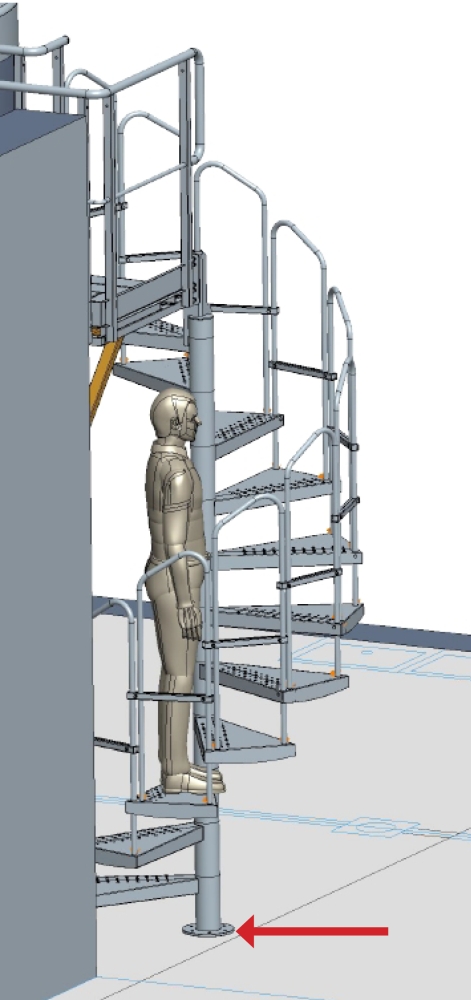

If the tanks are relatively low, the connectors on the lid can be accessed with a ladder. For safe access, the tanks are equipped with a ladder support. If the tanks are higher, it is necessary to ensure safe access to workstations at height by installing suitable staircases, platforms, and walkways.

Platform layout

The price of the platform is not calculated per running meter. The final price is determined based on multiple factors:

- possibility of configuration with standard segments (standard widths, lengths) https://sk-skrlj.com/en/platforms-and-staircases#filters

- complexity of the structure

- method of assembly for platforms and staircases (support elements, additional reinforcements)

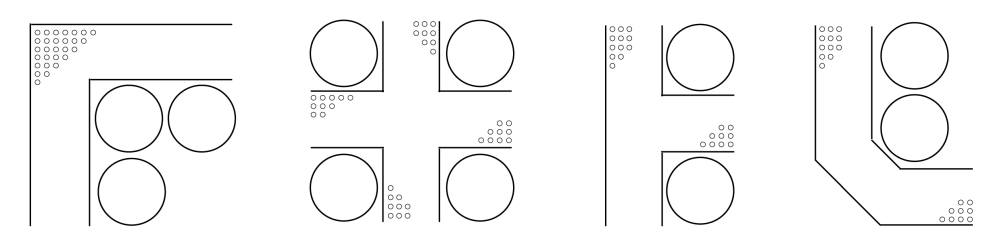

We therefore recommend that the platforms be constructed in straight lines and using standard segments. If your plan includes angular parts, we ask you to select one of the following configurations (if possible).

Tank fixing

For safety purposes, tall tanks with small diameters need to be fixed to the floor, wall, or a support element. Check if such fixing method is feasible in your winery. This is extremely important, particularly for platforms and staircases.

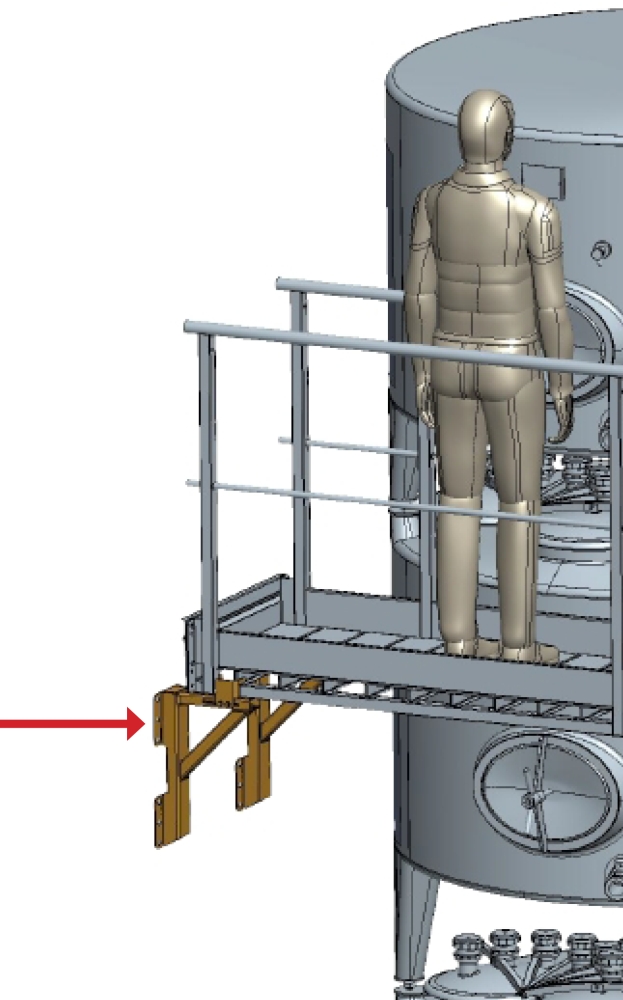

Another vital part of the planning and assembly process is the installation of angular support elements (brackets) on platforms. The brackets must be installed at a suitable height and in such a way that they do not obstruct the passageways or restrict the functionality of the tank equipment.

Outdoor installation

If the tanks and platforms are to be installed outdoors, check if the local regulations require a static calculation of the assembly (resistance to wind, earthquake, snow loads). Make sure you also check all environmental requirements.